Well I've got some progress. After trying a few places, I finally found a shop who could do the alignment.

Apparently my combination of low stance, modern wheels and the rear quarters that cover the top half or so of the rears make it near impossible to align. Or so it would seem.

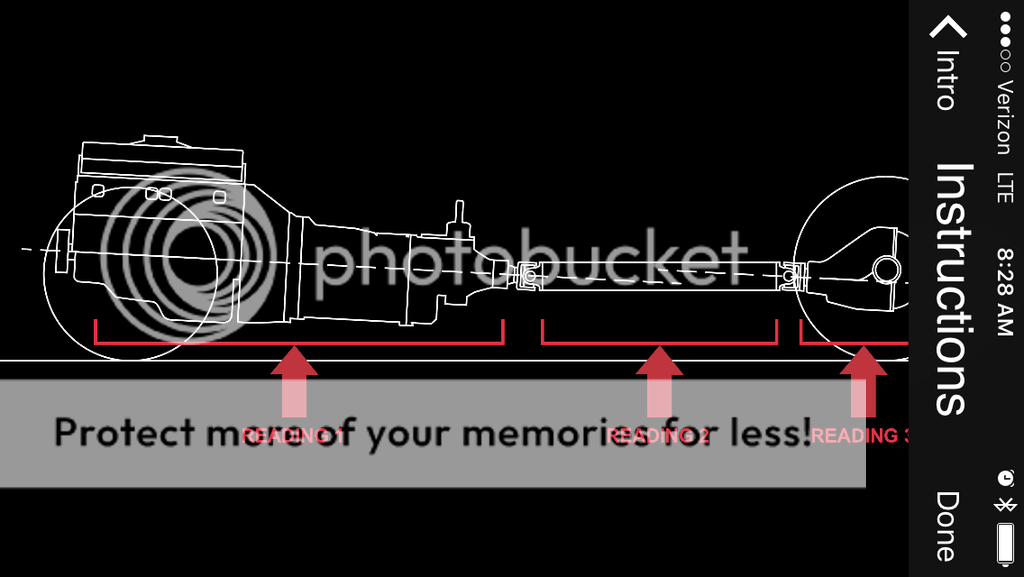

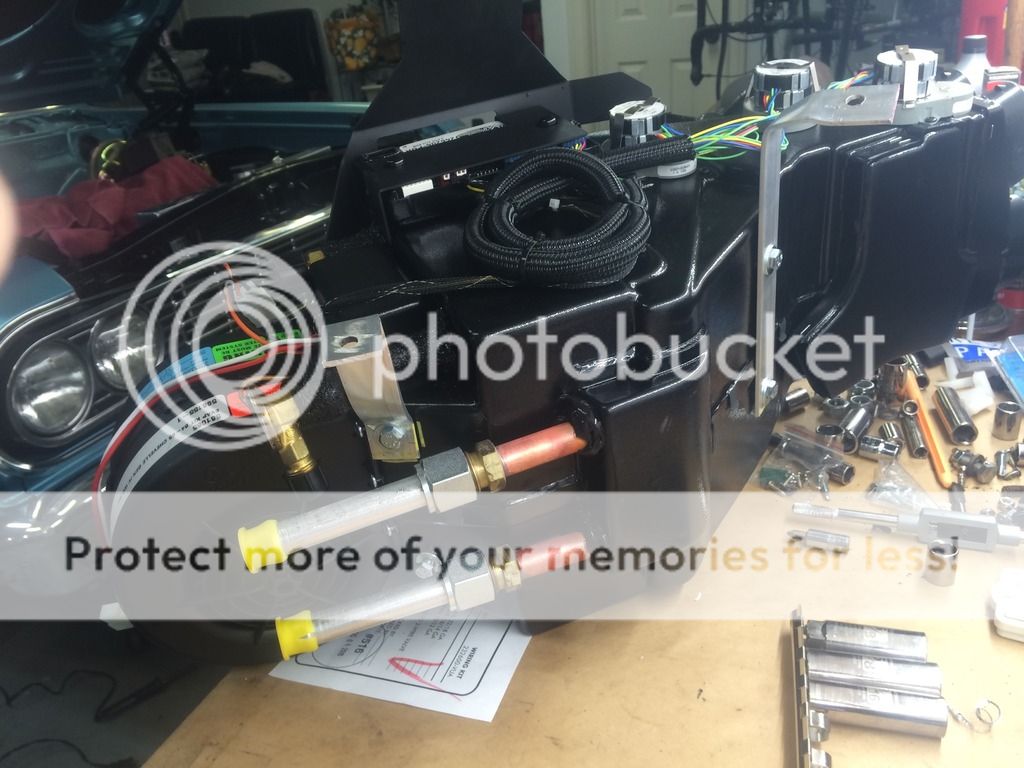

I forgot to take pics of it, but the machine looks similar to this:

The lasers in the elevated head read off the sensors that mount to wheels. You can see in this pic how the sensors mount to rim lip, which my wheels don't have. The short version is it is done. Victory.

Besides this major accomplishment, I've been tackling little items, like seat belts.

Next, some of my window track fuzzies came in, so I was able to finish the vent windows I started refurbishing way back when. So the front of the main door glass rides in this track:

Vent glass lower mount stud (becomes important later.)

Finished passenger side!

My temporary air conditioning:

The rear of the main door glass rides in this track. No one sells the specific felts for this track, so I had to find some general "mohair" strips. (Currently on order.)

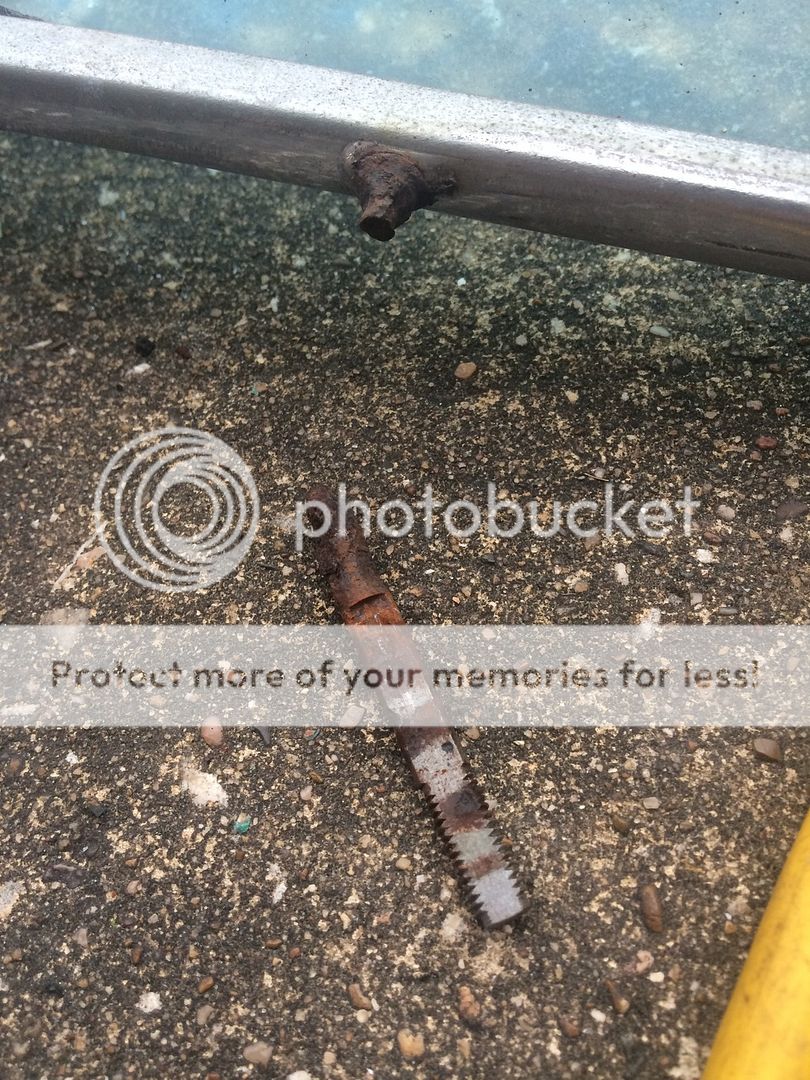

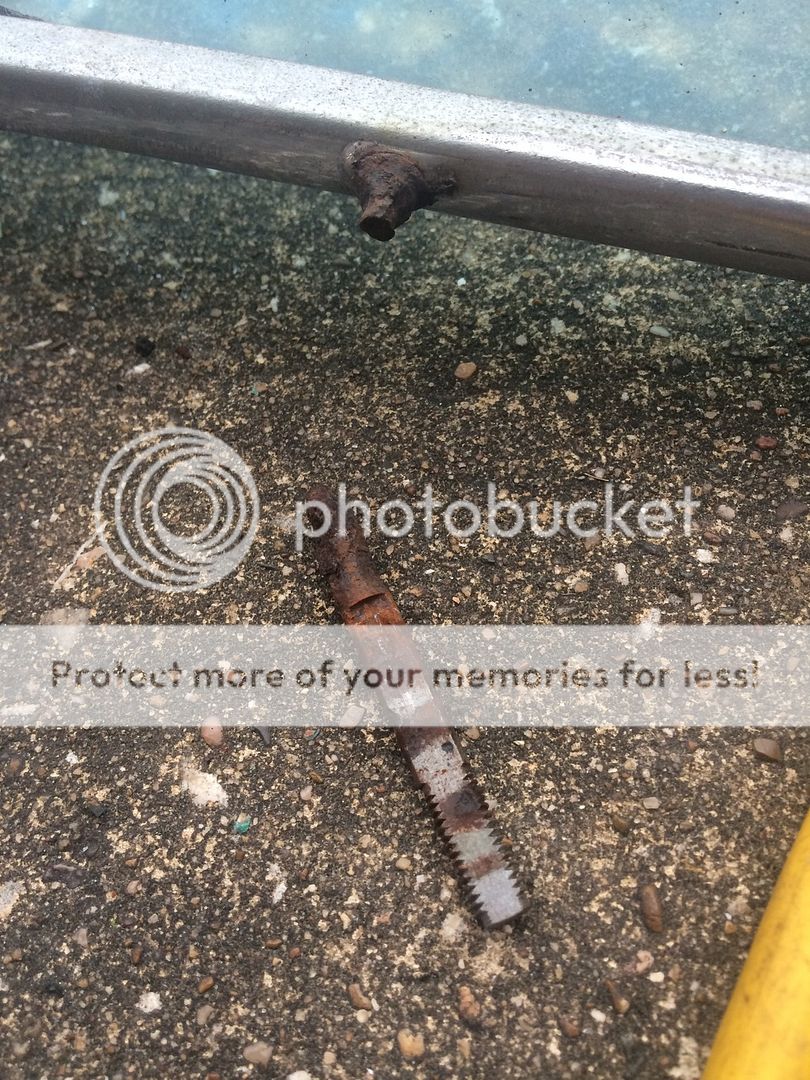

Old and crusty:

Quick was to clean these up!

Metro Molding sales guy was convinced the "vertical run channel" inserts would fit, I just needed to order 2; one set for vent window side, one for rear channel side. I was skeptical.....and rightly so:

More on that when the correct fuzzies arrive.

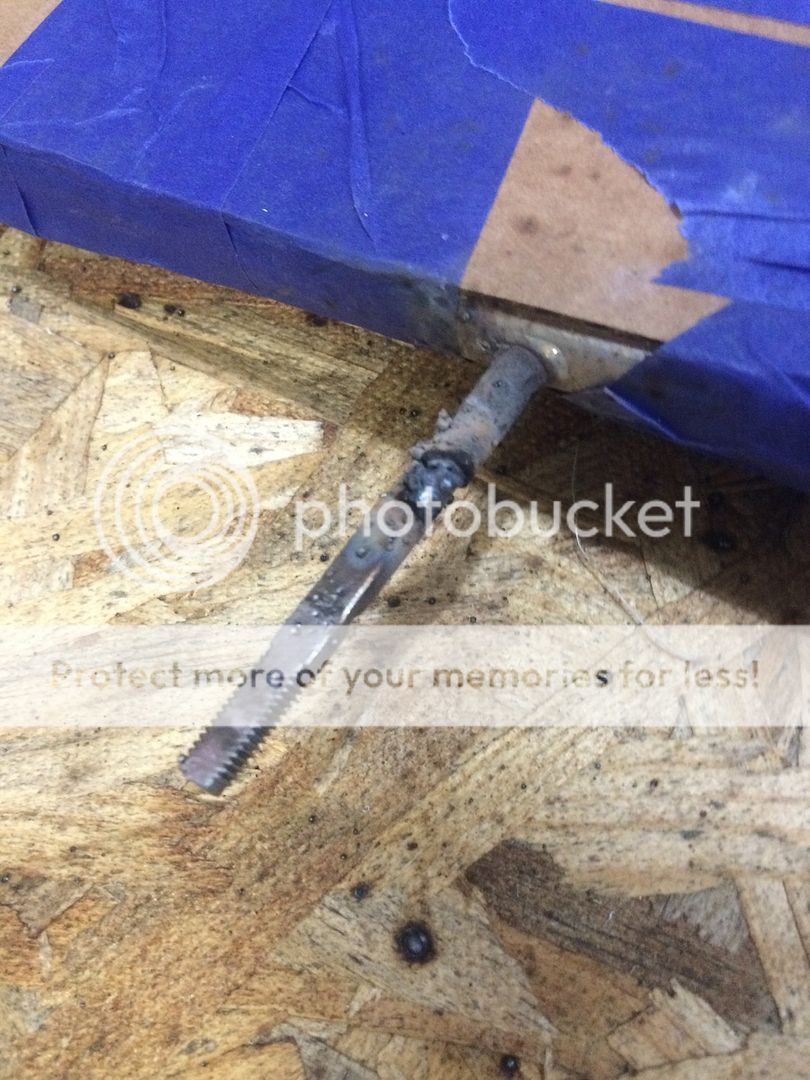

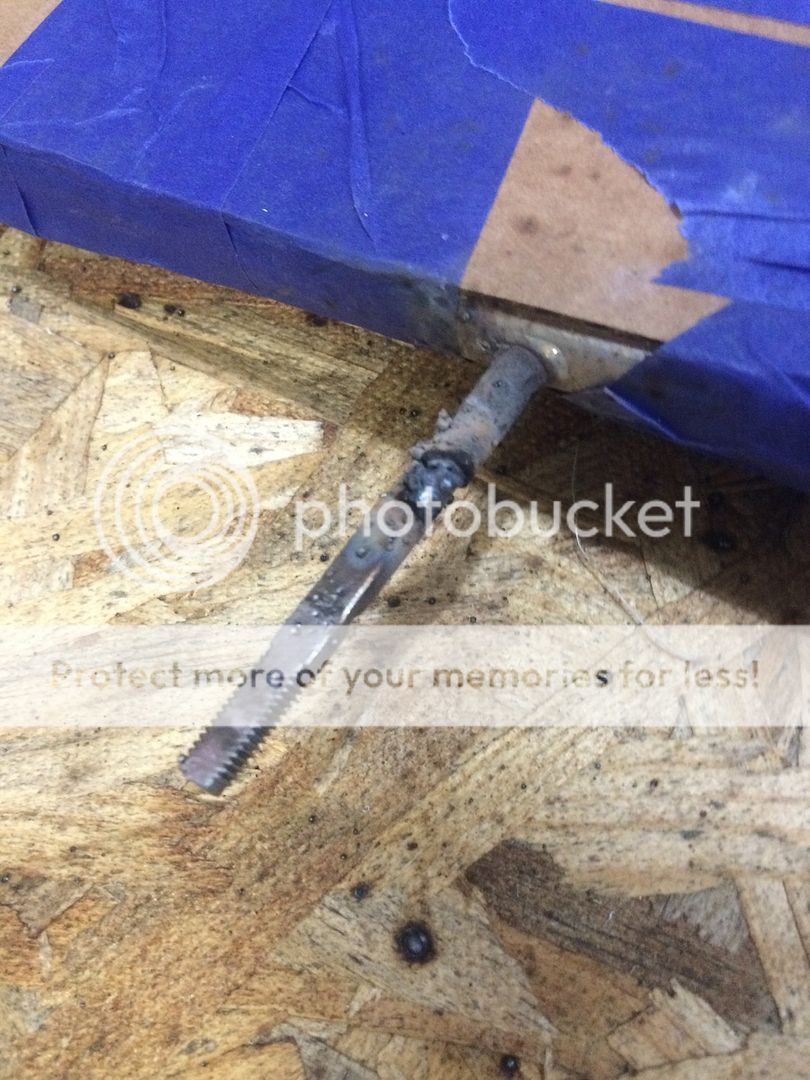

Onward to the next disaster. The driver side vent window didn't cooperate. The lower mounting stud broke off went I tried to disassemble it:

This is another part that is NOT available as a reproduction for this generation Chevelle. I would have to get creative. I had a spare vent window assembly from the passenger side. I decided to take it apart to see if I could use anything. This happened:

However, this is basically what I needed. The best solution became clear

It's not pretty, but it should hold.

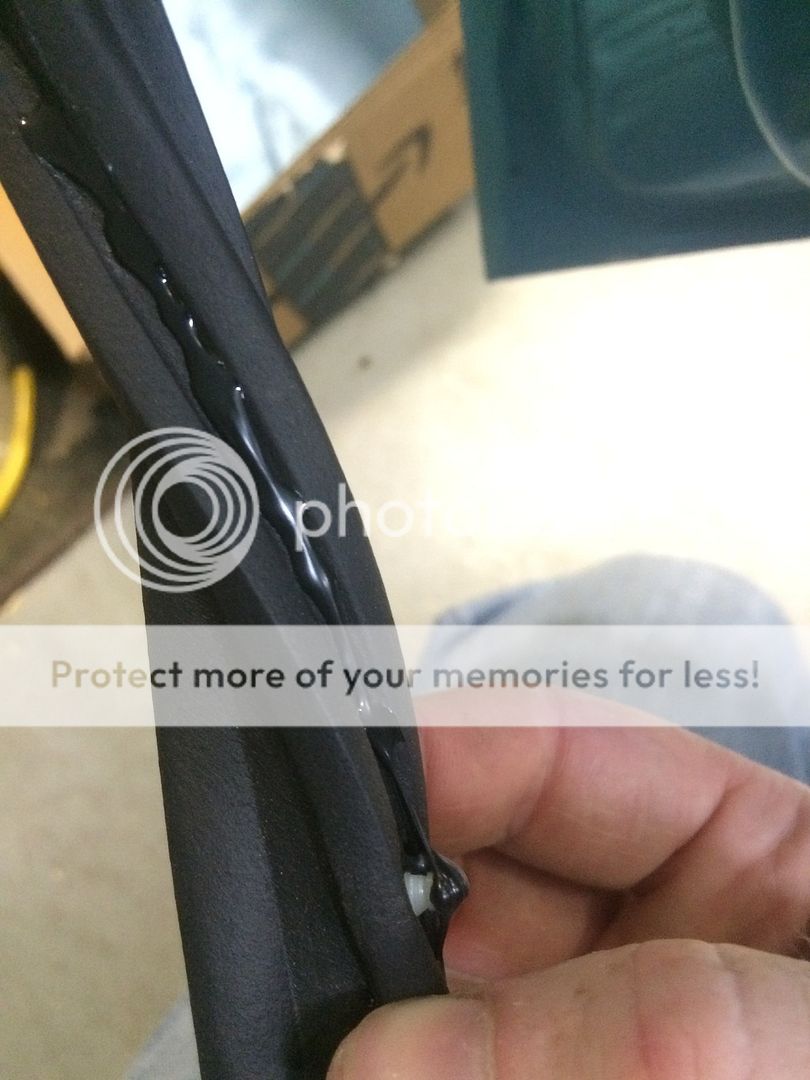

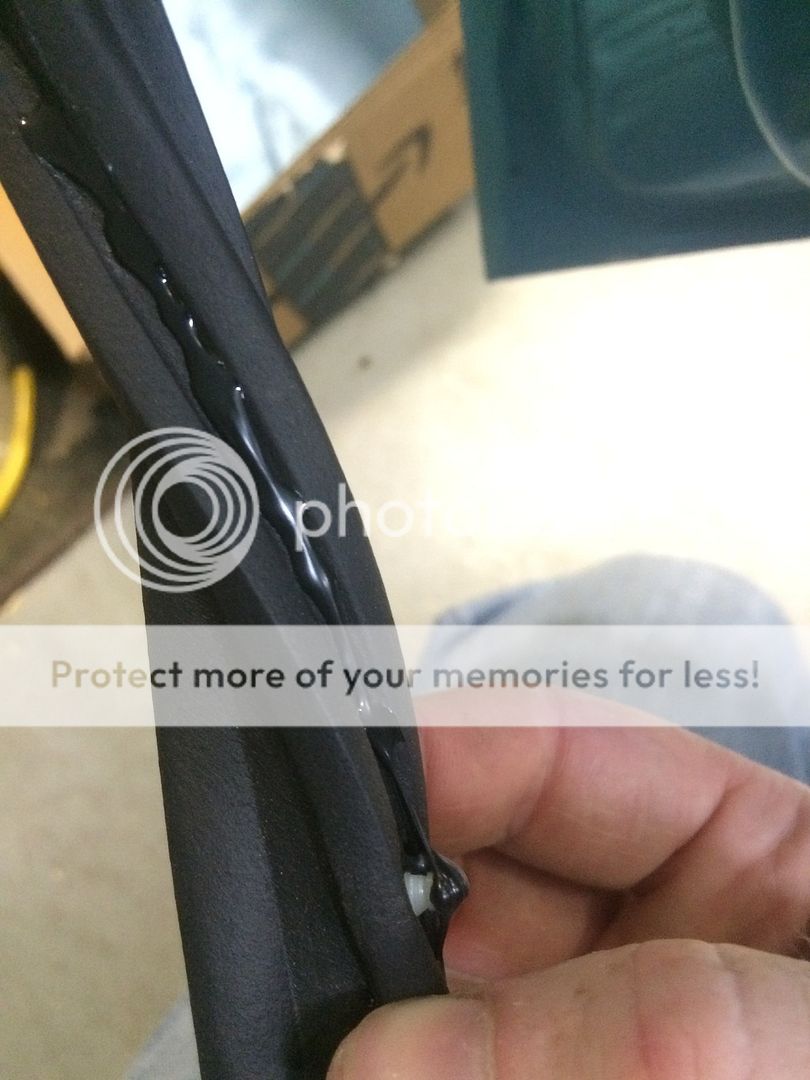

Last night I finished the driver's vent window install (no pics), and moved on to the door weatherstripping.

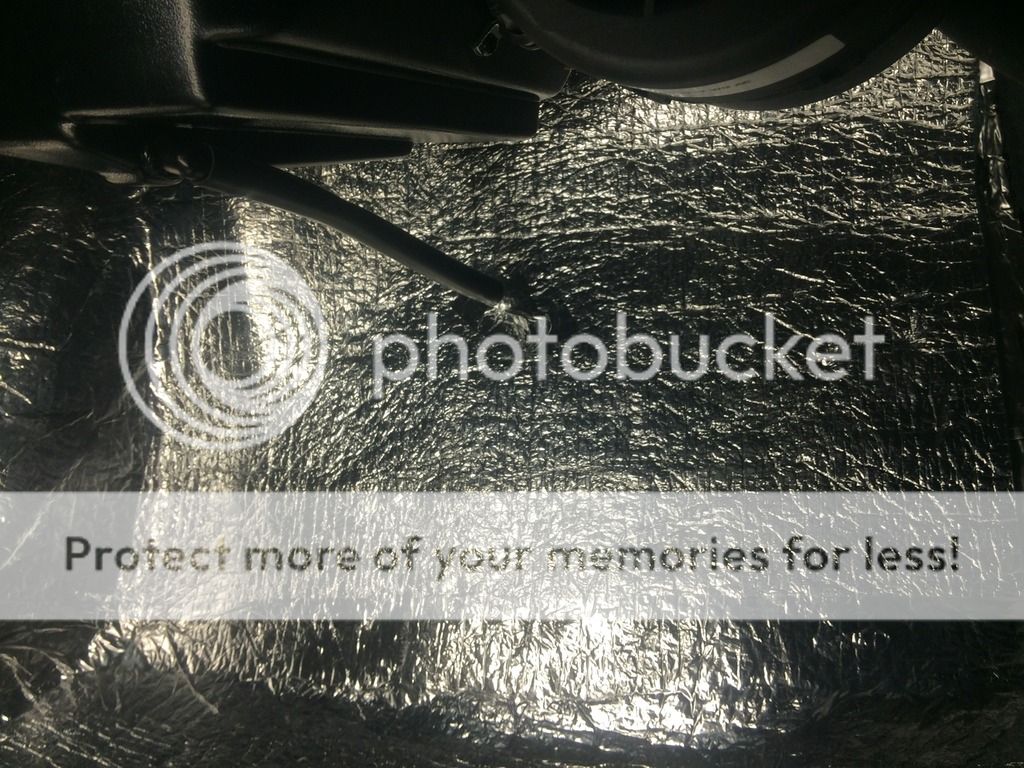

It went relatively smooth.

Using 3M Weatherstrip adhesive liberally but neatly.

On another note, my neighbor invited me to "cruise" up to the Lowe's cruise in last Friday with his buddies!

My neighbors are pretty cool. The line up includes a 55 & 56 Chevy, a 62 Impala 409, 66 Chevelle and a Hot Rod Coupe of some sort.

This was the first time I've driven the Chevelle up there, so it was kinda surreal. It's funny how many people recognized a new car among the usuals. I wasn't able to stay very long, so looking forward to next time. Maybe tonight! Hit me up if you see me.