Chevelle SS Resto-Mod Thread

101,266 Views |

491 Replies |

Last: 6 yr ago by lb3

quote:It's one guy, his company is called PZone (Powerzone).

Bro.

Who's the tuner?

I spent some time talking to him a while back and he seems very knowledgeable, and he will come to me.

This is from his add:

quote:

Some of our services range from camshaft consultation, 2bar, 3bar Speed Density tuning, forced Induction(Turbochargers, Superchargers) N2O, to mail order and remote tuning. We provide tuning solutions for street and drag strip applications with an overall objective of helping you go faster with a safe and sound comprehensive tune.

My experience includes several years of being an Automotive Computer Software Analyst specializing in LSX applications. I am also a Certified Advanced Tuner With HPtuners for GM vehicles.

Our services also include the following:

-perform real time scanning diagnostics

-complete street and dyno tunes

-modifications to troublesome DTC codes

-transmission tuning(If you do not like your current transmission performance, give us a call)

-Transmission performance packages for automatics and manuals.

-VATS and other modifications necessary for LSX swaps

-modifications to long term and short term fuel trims

-modifications to power enrichment and spark advance

-cooling fan activation temperature recalculated when adding colder t-stats(ex. 160F )

-modifications for stock vehicles and for fuel economy improvement

-modify speedometer calibrations for rear gear ratio and tire size changes

-modification to rev limiter(s)

-modifications for mild bolt-ons(intake, CAI, headers, exhaust improvement) to wild camshaft installs

And several other tables that we modify in ensure the best performance but SAFE!

Oh I forgot, passenger seat installed last night, as promised. These Procar seats are really a great deal.

I actually pulled it back out after this was taken and put all my "peel & seal" insulation down.

This side was easier due to the original floor pans still being intact. All the holes and studs where in the right place and my brackets dropped right in.

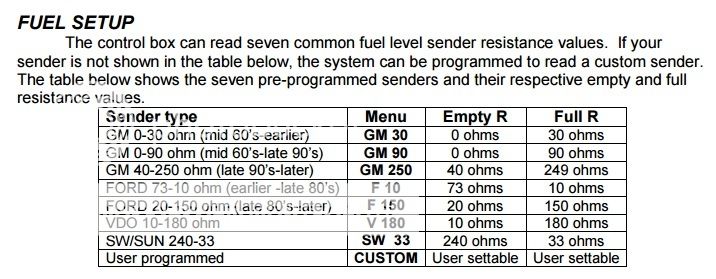

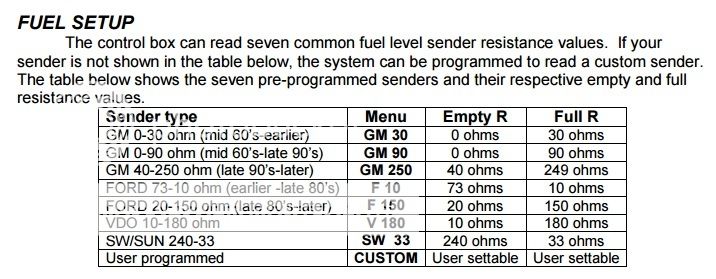

I also changed the fuel sender setting on my VHX gauge last night. I had been getting some sort of error code and the gauge was ready empty.

I think it was originally set on 0-30 ohm setting, changed it to 0-90 ohm.

Excerpt from user manual:

Guess I'll know more when I go fill the tank tomorrow!

I actually pulled it back out after this was taken and put all my "peel & seal" insulation down.

This side was easier due to the original floor pans still being intact. All the holes and studs where in the right place and my brackets dropped right in.

I also changed the fuel sender setting on my VHX gauge last night. I had been getting some sort of error code and the gauge was ready empty.

I think it was originally set on 0-30 ohm setting, changed it to 0-90 ohm.

Excerpt from user manual:

Guess I'll know more when I go fill the tank tomorrow!

Well that didn't go well.

PCM was locked by Nelson Performance, which is their standard practice when they perform a tune. Protects their "proprietary information."

So the tuning session never really got off the ground.

I pulled the PCM Sunday, mailed it to Nelson yesterday. They will unlock, revert to OEM tune, and send back to me.

I'm only out shipping. And time and emotion thinking I'd be driving this thing around by now.

PCM was locked by Nelson Performance, which is their standard practice when they perform a tune. Protects their "proprietary information."

So the tuning session never really got off the ground.

I pulled the PCM Sunday, mailed it to Nelson yesterday. They will unlock, revert to OEM tune, and send back to me.

I'm only out shipping. And time and emotion thinking I'd be driving this thing around by now.

Try to think of it as "tantric" hot-rodding.

That's pretty appropriate really, based on the contortions needed to try to remove that PCM.

It's a great location, hidden, high up away from water, close enough to engine without having to extend wires.

It's a terrible location if you need to remove it.

It's a great location, hidden, high up away from water, close enough to engine without having to extend wires.

It's a terrible location if you need to remove it.

Super long update:

Well this weekend was unfortunately another tuning session that didn't go as planned.

I'm not sure the severity of what is happening, so any knowledgeable input would be appreciated.

Here is the rundown:

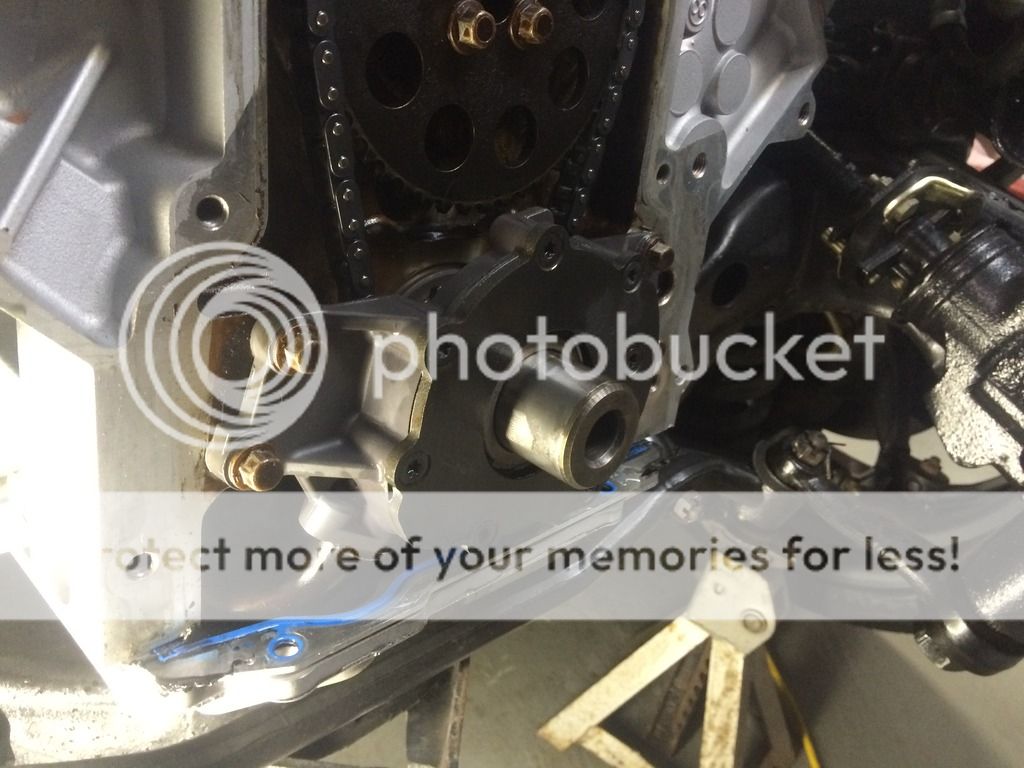

Tuning session started with troubleshooting a few issues with sensors and the like, as well as getting a good baseline idle established.

After that was sound, we headed out for a drive, going south on 288. The tuner would log data from me driving, then we would stop and he would edit the file, while I checked for leaks, issues or concerns. Things were going great, no issues.

I started hearing some increased engine noise that I initially thought was exhaust leak. I also was observing the oil pressure running a bit lower, maybe around 20 psi. I more or less attributed this to the engine reallly getting up to operating temperature for the first time.

We had almost finished the normal driving tuning and were only going to do the WOT (wide open throttle) runs to get the upper powerband tuned.

We did one 3rd gear pull to about 4k RPM. The engine noise got much louder and I immediately noticed the oil psi gauge on 0!

I shut it off and pulled over. No leaks, plenty of oil on dipstick that looked clean. After thinking and checking we decided to start it up again and the oil pressure came up to about 10 psi and stabilized. Mystery noise was present but not as loud.

We made decision to limp it home and psi stayed around 10 or so.

Made it home and started it again to listen through a hose to pinpoint noise. Seems to emanate from valve train area. I next drained oil, no obvious shavings, flakes, glittery appearance or anything. Oil was dirty for low miles, but otherwise fine.

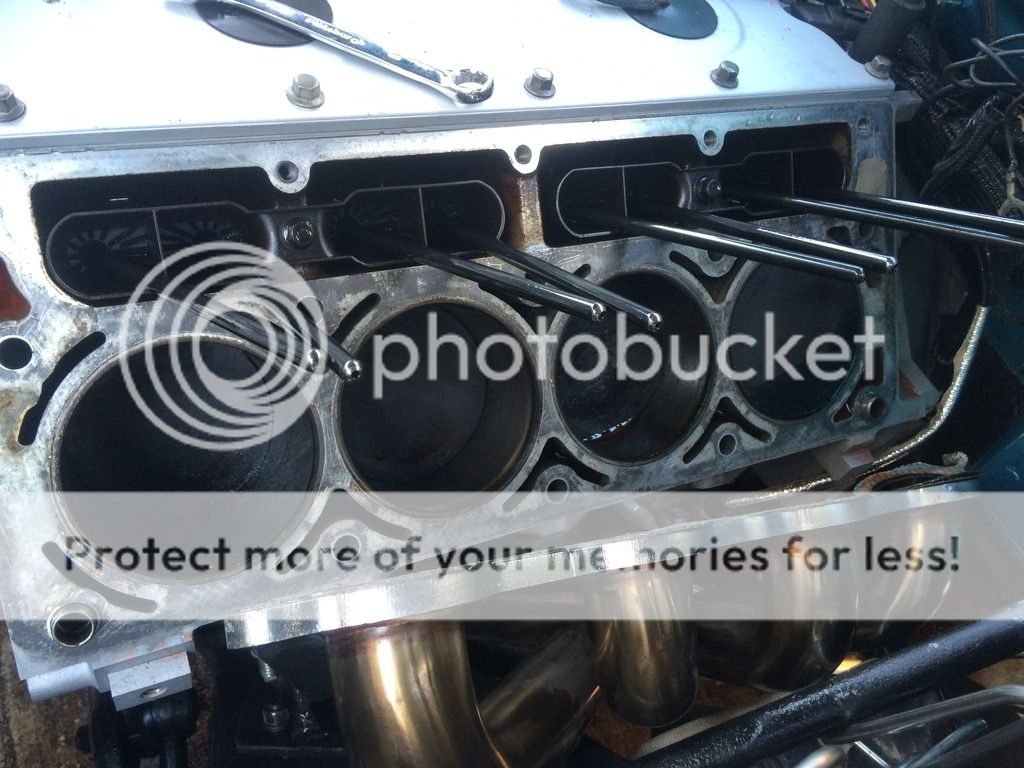

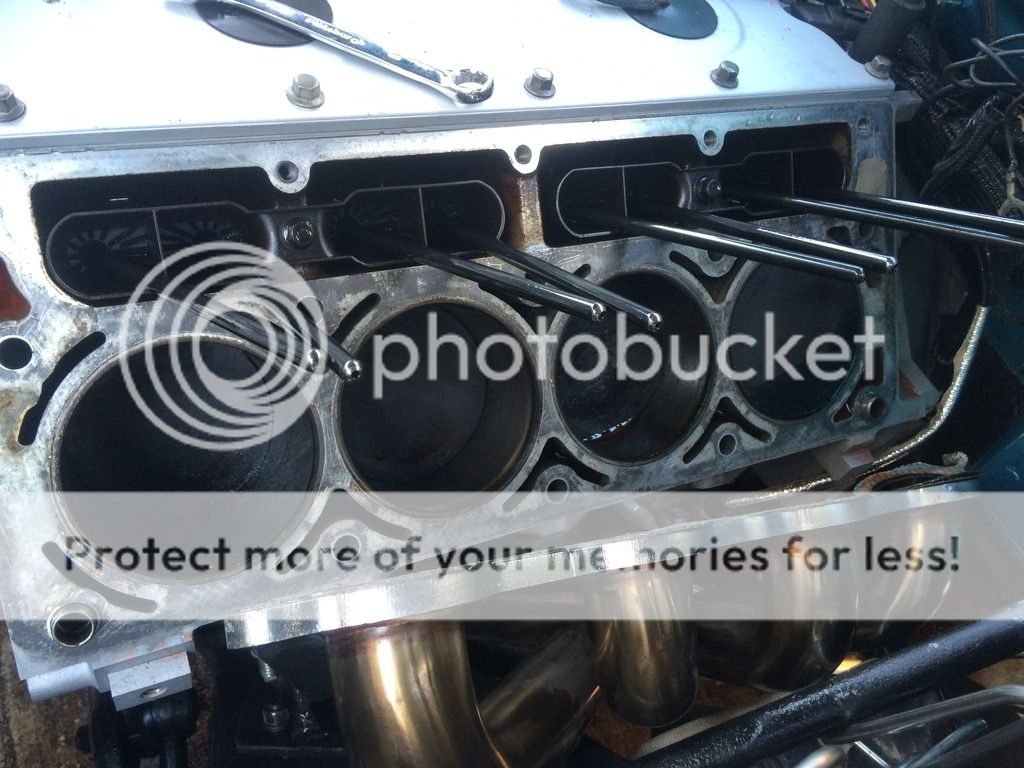

Decided to pull valve cover, rockers were all fine, none lose or damaged. At this point, I figure I'm all in, so I go ahead and pull the head to inspect for cam, lifter or pushrod damage.

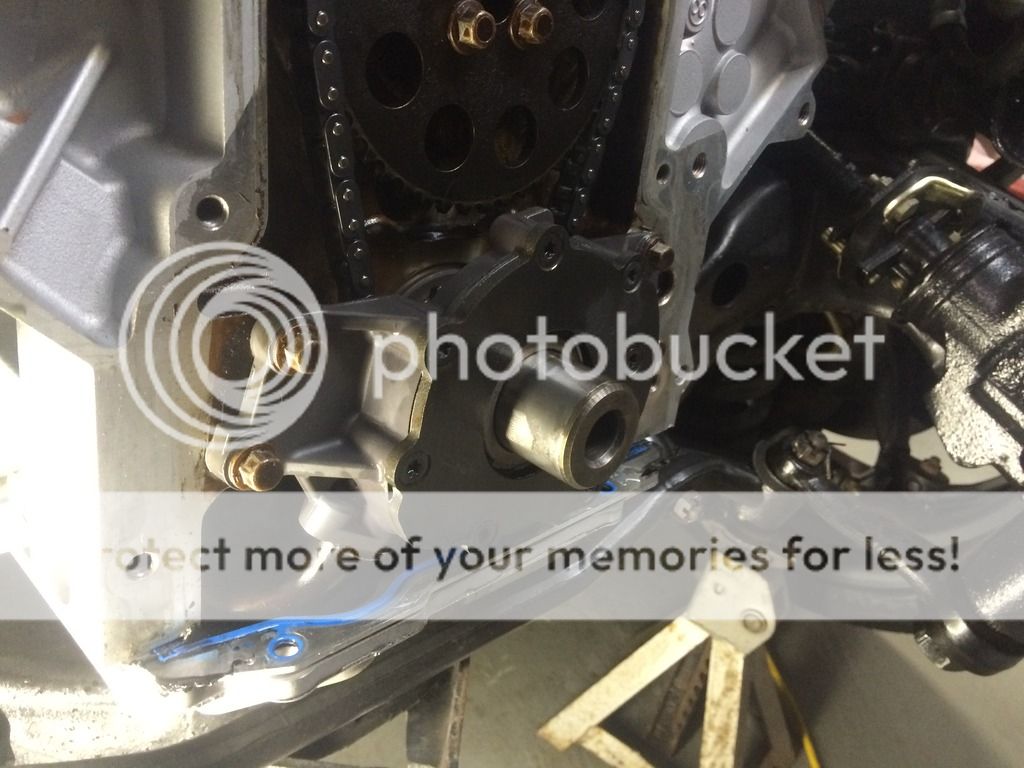

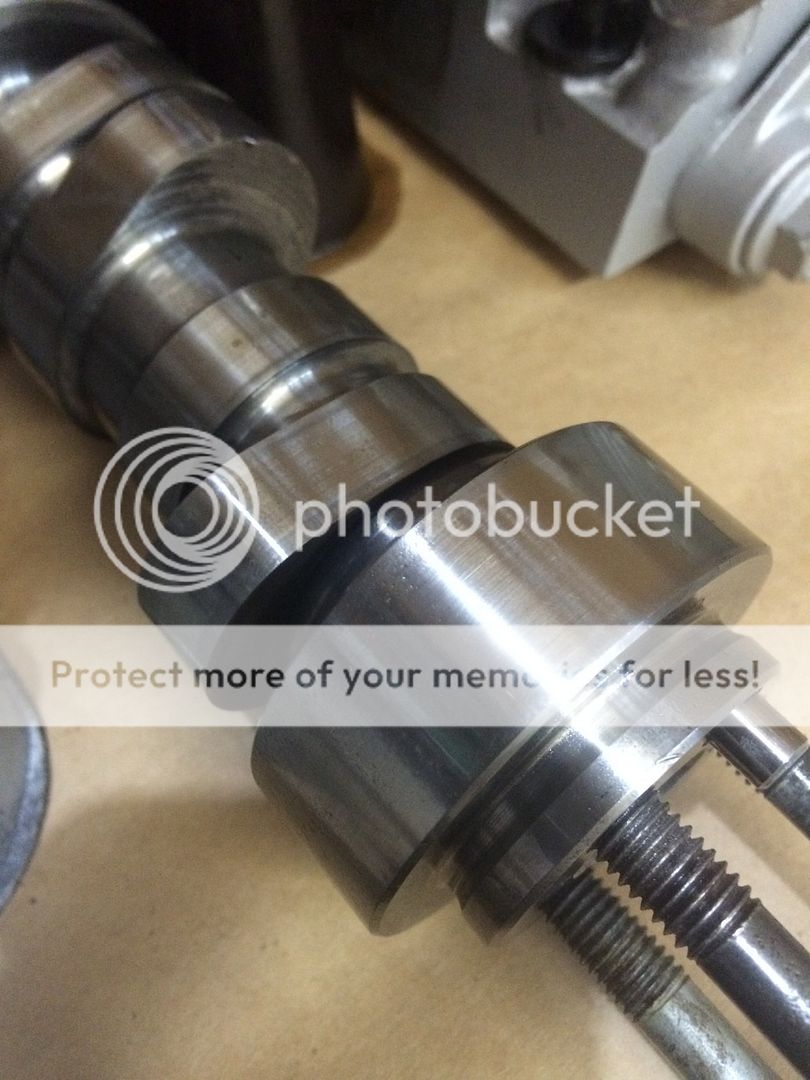

Cam lobes that I could see seemed fine, with minimal mating wear:

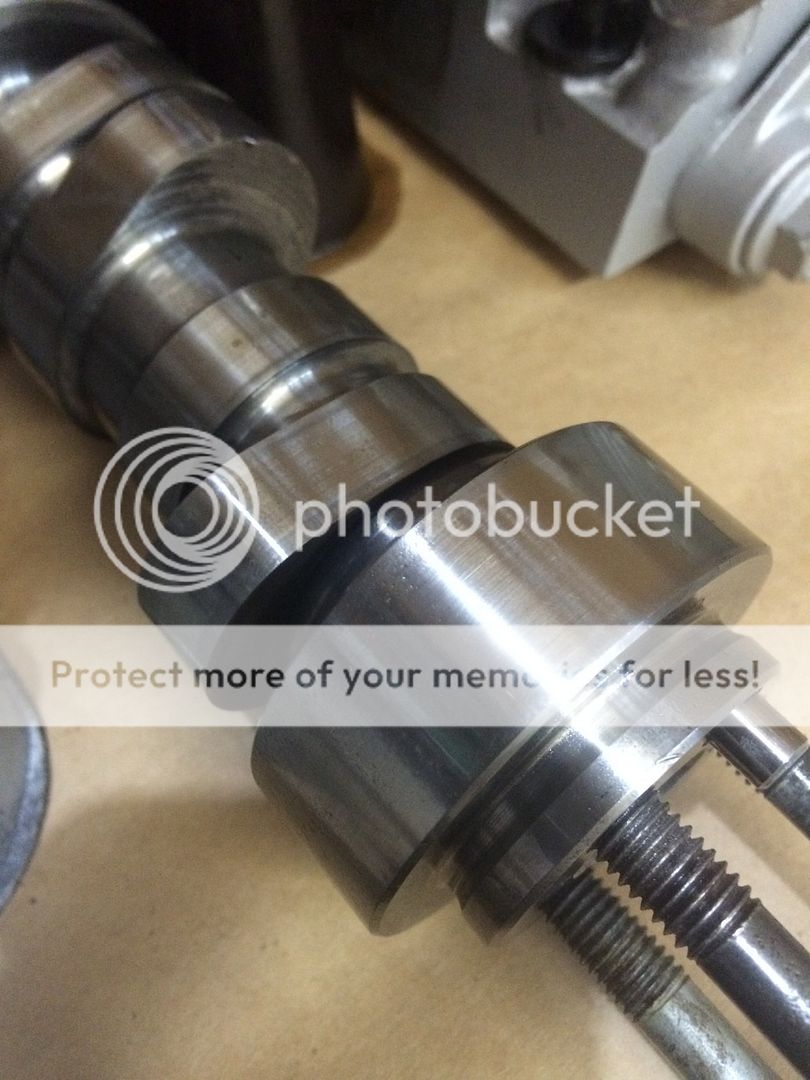

Same for lifters:

Pistons and bores look fine, as well as combustion chambers on the heads, save for some carbon build up probably from when it was running rich. Plugs also seem ok.

I also cut the oil filter open to look for any sign of internal wear.

At this point I'm honed in on the oil pump, as there are many documented occurrences of the early LS oil pump failures. The pump's bypass valve sticks open and you basically get a very low pressure condition.

My presumption is the pump started failing, and pressure was too low to get oil up (and keep it) in the valve train, which was cause the lifters to clatter.

So, that's where I am now. Got a Melling 10295 pump coming tomorrow, I'll pull the old one tonight, maybe it will be obvious.

I've spent hours on LS1tech forums reading about all the disasters that could be in play. Spun bearings being the worst I can think of. However, I for sure never heard any knocking.

I feel like at this point I can also rule out major cam damage, based on what I saw.

Any comforting words from the autoboard experts?

All issues aside, when the car was running, it felt GREAT! I didn't have a chance to really open it up, but it was definitely pulling very hard when I would get on it. Hoping it's just a pump so I can start seeing what this thing will do!!

Well this weekend was unfortunately another tuning session that didn't go as planned.

I'm not sure the severity of what is happening, so any knowledgeable input would be appreciated.

Here is the rundown:

Tuning session started with troubleshooting a few issues with sensors and the like, as well as getting a good baseline idle established.

After that was sound, we headed out for a drive, going south on 288. The tuner would log data from me driving, then we would stop and he would edit the file, while I checked for leaks, issues or concerns. Things were going great, no issues.

I started hearing some increased engine noise that I initially thought was exhaust leak. I also was observing the oil pressure running a bit lower, maybe around 20 psi. I more or less attributed this to the engine reallly getting up to operating temperature for the first time.

We had almost finished the normal driving tuning and were only going to do the WOT (wide open throttle) runs to get the upper powerband tuned.

We did one 3rd gear pull to about 4k RPM. The engine noise got much louder and I immediately noticed the oil psi gauge on 0!

I shut it off and pulled over. No leaks, plenty of oil on dipstick that looked clean. After thinking and checking we decided to start it up again and the oil pressure came up to about 10 psi and stabilized. Mystery noise was present but not as loud.

We made decision to limp it home and psi stayed around 10 or so.

Made it home and started it again to listen through a hose to pinpoint noise. Seems to emanate from valve train area. I next drained oil, no obvious shavings, flakes, glittery appearance or anything. Oil was dirty for low miles, but otherwise fine.

Decided to pull valve cover, rockers were all fine, none lose or damaged. At this point, I figure I'm all in, so I go ahead and pull the head to inspect for cam, lifter or pushrod damage.

Cam lobes that I could see seemed fine, with minimal mating wear:

Same for lifters:

Pistons and bores look fine, as well as combustion chambers on the heads, save for some carbon build up probably from when it was running rich. Plugs also seem ok.

I also cut the oil filter open to look for any sign of internal wear.

At this point I'm honed in on the oil pump, as there are many documented occurrences of the early LS oil pump failures. The pump's bypass valve sticks open and you basically get a very low pressure condition.

My presumption is the pump started failing, and pressure was too low to get oil up (and keep it) in the valve train, which was cause the lifters to clatter.

So, that's where I am now. Got a Melling 10295 pump coming tomorrow, I'll pull the old one tonight, maybe it will be obvious.

I've spent hours on LS1tech forums reading about all the disasters that could be in play. Spun bearings being the worst I can think of. However, I for sure never heard any knocking.

I feel like at this point I can also rule out major cam damage, based on what I saw.

Any comforting words from the autoboard experts?

All issues aside, when the car was running, it felt GREAT! I didn't have a chance to really open it up, but it was definitely pulling very hard when I would get on it. Hoping it's just a pump so I can start seeing what this thing will do!!

Your loss of oil pressure sounds exactly like what the OE engine in Basic Birch did.

Whenever I finally change the cam in a LS, I'll be replacing the oil pump while I'm there.

Just saw your bit about Nelson's PCM, I need to send mine back to them as well. Still can't decide if I'll use my local tuner for the new tune or if I'm biting the bullet and buying everything needed to tune and start the learning process.

Whenever I finally change the cam in a LS, I'll be replacing the oil pump while I'm there.

Just saw your bit about Nelson's PCM, I need to send mine back to them as well. Still can't decide if I'll use my local tuner for the new tune or if I'm biting the bullet and buying everything needed to tune and start the learning process.

quote:Did you ever open that motor up to see what the issue was? I know I was careful about the pickup tube o-ring.

Your loss of oil pressure sounds exactly like what the OE engine in Basic Birch did.

I also had the thought today about how that motor wouldn't build any oil pressure when I was doing the first startup under only cranking power.....wonder if that was a sign of an under-performing pump...?

Never did open it up, but fairly certain that's what it was. I know that o-ring was good.

In retrospect, it was stupid, stupid, stupid not to change that pump when I was holding it in my hand last spring.

Kinda like that water pump that ended with the exact same result.

Kinda like that water pump that ended with the exact same result.

Got the '67 goat out of the shop. Major improvement on the suspension. Drives smooth.

While in the shop, I saw a 1969 Chevelle sitting on a custom frame, with a 2016 Corvette L06 engine and suspension. Total custom job. They're going to build the interior just like to 69 Chevelle stock, but everything electronic and new. From the outside and interior you won't be able to tell that runs on a Vette foundation.

While in the shop, I saw a 1969 Chevelle sitting on a custom frame, with a 2016 Corvette L06 engine and suspension. Total custom job. They're going to build the interior just like to 69 Chevelle stock, but everything electronic and new. From the outside and interior you won't be able to tell that runs on a Vette foundation.

quote:We will need pics of these items of which you speak!

Got the '67 goat out of the shop. Major improvement on the suspension. Drives smooth.

While in the shop, I saw a 1969 Chevelle sitting on a custom frame, with a 2016 Corvette L06 engine and suspension. Total custom job. They're going to build the interior just like to 69 Chevelle stock, but everything electronic and new. From the outside and interior you won't be able to tell that runs on a Vette foundation.

Almost have the motor back together, just need to put on the valve cover, reconnect wiring, and refill with fluids.

Hope to crank it back up tonight.

Will post update soon.

quote:Quick turnaround. Good luck, hopefully this solves the issue.quote:We will need pics of these items of which you speak!

Got the '67 goat out of the shop. Major improvement on the suspension. Drives smooth.

While in the shop, I saw a 1969 Chevelle sitting on a custom frame, with a 2016 Corvette L06 engine and suspension. Total custom job. They're going to build the interior just like to 69 Chevelle stock, but everything electronic and new. From the outside and interior you won't be able to tell that runs on a Vette foundation.

Almost have the motor back together, just need to put on the valve cover, reconnect wiring, and refill with fluids.

Hope to crank it back up tonight.

Will post update soon.

Weekend update, another long one.

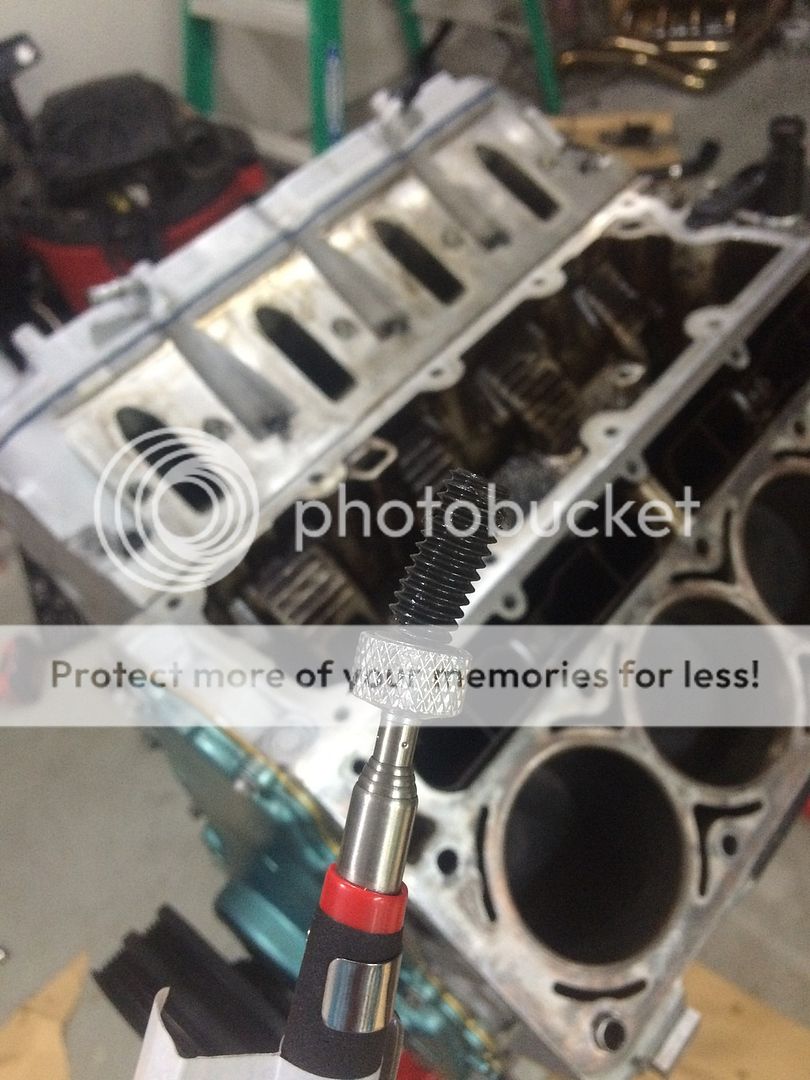

Thursday night I got the old oil pump off and new oil pump and cylinder head installed.

Not a bad job but the hardest part is getting the balancer/pulley off.

The second hardest part is accessing the pickup tube mount bolt. You have to drop the pan a bit to get to it.

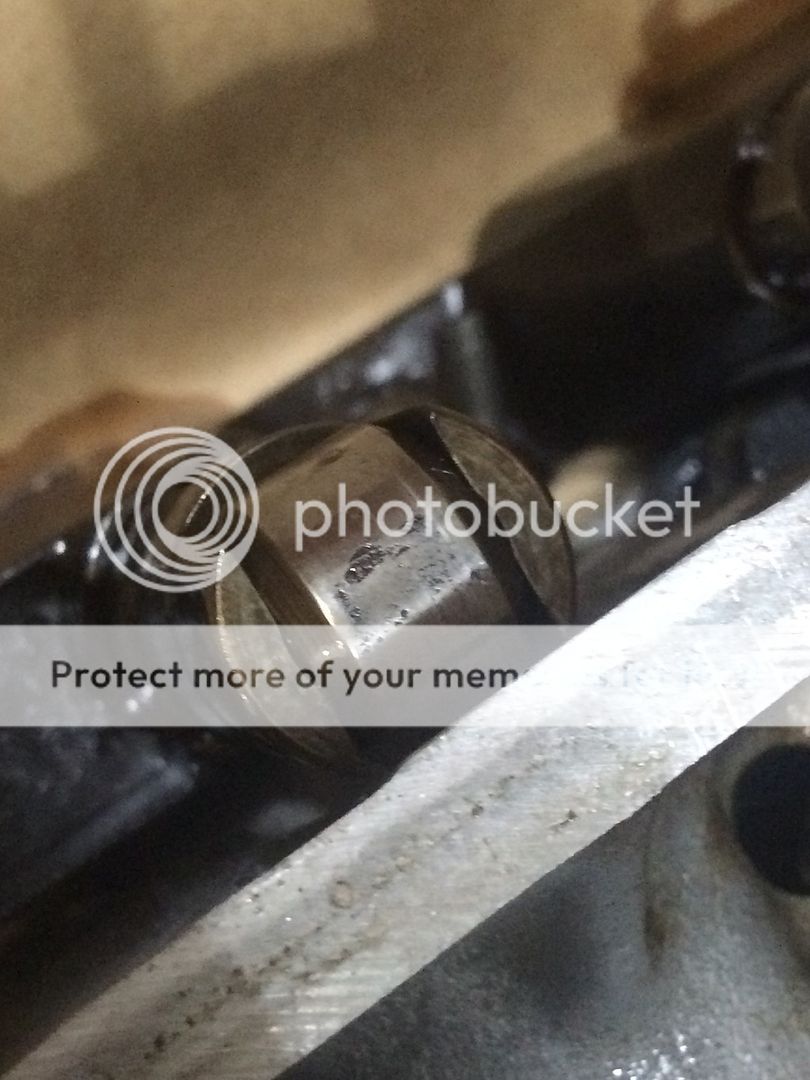

Here it is loosened, I stuff a towel behind in case the bolt fell out. Wrapped some bailing wire around the bolt to hang on to it.

Old pump removed:

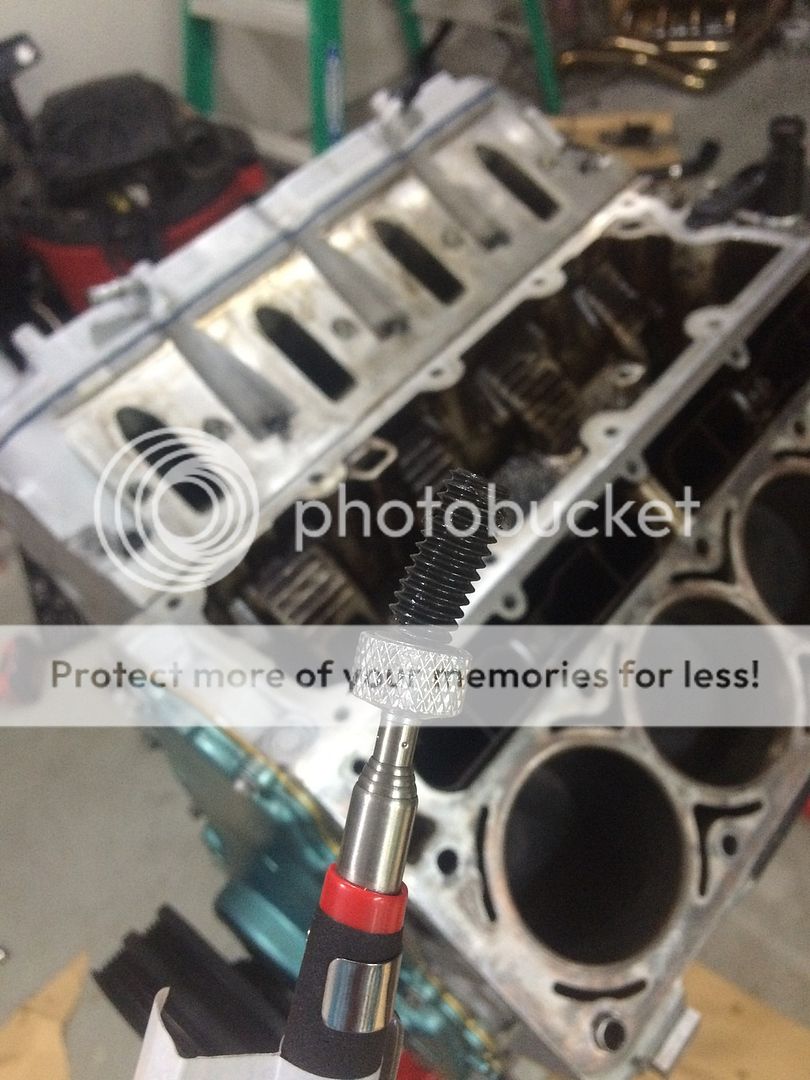

I pulled out the pressure relief assembly hoping to determine if it had been hanging up. Took a video to try and show what looked like some galling. Not sure though:

Relief valve piston

One well documented problem area is getting the pickup tube o-ring pinched in the oil pump recess.

Obviously that isn't my issue:

Here is the new pump, melling 10295.

New pump installed

Decided to upgrade to a ARP crank pulley bolt, as the OE version is torque to yield. Already had to buy one, so it's a paperweight now.

Saw lots of people on LS1tech recommending this copper gasket spray. Thought I'd give it a try on the headgasket. Anyone used it?

Friday night, I got all the fluids topped off and everything buttoned up. Cranked it with coil packs unhooked and got oil pressure built up pretty good. So that was a good sign. Here is video of the startup.

Oil pressure stayed above 50 for quite a while just idling in the driveway.

I was thinking, "Hot damn! That was the problem!"

After checking for leaks everywhere, I took it around the block for a test. Got out on open road and did a good part-throttle pull in second and third gear. By the time I got to the stoplight at the corner, pressure was already dropping to below 20. It hit 0 before I could even get home, so I limped it back and shut it down.

I wracked my brain trying to figure out why this would happen, but didn't come up with much.

One thought is that maybe the pick up tube is getting clogged??

Saturday I tried to get pressure again by cranking and it wouldn't come up at all. I even pulled the oil galley port that is right off the pump and didn't get a single drop to come out.

It should be gushing out of that port when cranking?!

So, I pulled the oil again, and in the sunlight I could see what looked like gold-ish streaks as well as the dreaded "stripper glitter." So at this point I'm assuming I have a cam bearing spun or going out.

I decided to not risk ruining my cam or any more parts, and pull the motor. It sucks but it needs to be addressed.

As of today (Sunday) everything is unhooked, ready to come out, just waiting for someone to help me pull it.

I may tear it down myself and see the damage or just take the short block to Owen's Machine shop and let them diagnose and rebuild. I'll probably call them Monday to see what they say first.

Nothing comes easy on this project, it seems!

Thursday night I got the old oil pump off and new oil pump and cylinder head installed.

Not a bad job but the hardest part is getting the balancer/pulley off.

The second hardest part is accessing the pickup tube mount bolt. You have to drop the pan a bit to get to it.

Here it is loosened, I stuff a towel behind in case the bolt fell out. Wrapped some bailing wire around the bolt to hang on to it.

Old pump removed:

I pulled out the pressure relief assembly hoping to determine if it had been hanging up. Took a video to try and show what looked like some galling. Not sure though:

Relief valve piston

One well documented problem area is getting the pickup tube o-ring pinched in the oil pump recess.

Obviously that isn't my issue:

Here is the new pump, melling 10295.

New pump installed

Decided to upgrade to a ARP crank pulley bolt, as the OE version is torque to yield. Already had to buy one, so it's a paperweight now.

Saw lots of people on LS1tech recommending this copper gasket spray. Thought I'd give it a try on the headgasket. Anyone used it?

Friday night, I got all the fluids topped off and everything buttoned up. Cranked it with coil packs unhooked and got oil pressure built up pretty good. So that was a good sign. Here is video of the startup.

Oil pressure stayed above 50 for quite a while just idling in the driveway.

I was thinking, "Hot damn! That was the problem!"

After checking for leaks everywhere, I took it around the block for a test. Got out on open road and did a good part-throttle pull in second and third gear. By the time I got to the stoplight at the corner, pressure was already dropping to below 20. It hit 0 before I could even get home, so I limped it back and shut it down.

I wracked my brain trying to figure out why this would happen, but didn't come up with much.

One thought is that maybe the pick up tube is getting clogged??

Saturday I tried to get pressure again by cranking and it wouldn't come up at all. I even pulled the oil galley port that is right off the pump and didn't get a single drop to come out.

It should be gushing out of that port when cranking?!

So, I pulled the oil again, and in the sunlight I could see what looked like gold-ish streaks as well as the dreaded "stripper glitter." So at this point I'm assuming I have a cam bearing spun or going out.

I decided to not risk ruining my cam or any more parts, and pull the motor. It sucks but it needs to be addressed.

As of today (Sunday) everything is unhooked, ready to come out, just waiting for someone to help me pull it.

I may tear it down myself and see the damage or just take the short block to Owen's Machine shop and let them diagnose and rebuild. I'll probably call them Monday to see what they say first.

Nothing comes easy on this project, it seems!

Dang.....

On a positive note, this is when I would typically recommend a LS swap, but you're already in the process of doing so.

Everything will be worth it.

Everything will be worth it.

Do you remember what size socket you used on the stock crank bolt? Google has been of no assistance.

Talk about a punch to the gut. Sorry to hear about the setbacks.

If you have to pull it, might as well as mod if farther ;-).

quote:24mm I believe...

Do you remember what size socket you used on the stock crank bolt? Google has been of no assistance.

quote:I've considered this....a buddy of mine has a forged Eagle crank he'd sell me, but I'd have to go to 6.125" rods I believe.

If you have to pull it, might as well as mod if farther ;-).

Honestly at this point, I'd like to ensure the bearings are all in good shape, replace if necessary, and get it back in the car.

Now if I have some spun bearings and/or rod or crank journal damage, then I may revisit the upgrades....we shall see.

quote:Agree. When do you find out ?quote:I've considered this....a buddy of mine has a forged Eagle crank he'd sell me, but I'd have to go to 6.125" rods I believe.

If you have to pull it, might as well as mod if farther ;-).

Honestly at this point, I'd like to ensure the bearings are all in good shape, replace if necessary, and get it back in the car.

Now if I have some spun bearings and/or rod or crank journal damage, then I may revisit the upgrades....we shall see.

Got it pulled Monday night and have it on the engine stand. Nothing real obvious as far as the bottom end goes. The rear two crank counter-weights do have a little rust on them, but that's about it. Hoping to pull the heads tonight, possibly the cam and whatever else I can get to.

The machine shop charges $125 for a tear down, so I think I'll do that myself and just mark all the parts so we know what goes where.

I ordered a new rear cover, the old one's bolt holes were both stripped out, so I was getting some leaks where it mates to the oil pan.

The machine shop charges $125 for a tear down, so I think I'll do that myself and just mark all the parts so we know what goes where.

I ordered a new rear cover, the old one's bolt holes were both stripped out, so I was getting some leaks where it mates to the oil pan.

Tough break

I am waiting to see what upgrades you decide to do.

wondering what it costs these days, to have an engine dyno'd/bench tested. make sure everyhting is right before you go through the hassle of reinstalling in the car

I am waiting to see what upgrades you decide to do.

wondering what it costs these days, to have an engine dyno'd/bench tested. make sure everyhting is right before you go through the hassle of reinstalling in the car

quote:Good question, I know Owen's has an engine dyno, they were running it once when I was there.

Tough break

I am waiting to see what upgrades you decide to do.

wondering what it costs these days, to have an engine dyno'd/bench tested. make sure everyhting is right before you go through the hassle of reinstalling in the car

Hoping to go by there and drop things off tomorrow morning, I'll try to remember to ask.

Well on the whole, everything checked out OK. Main and rod bearings looked fine, so they put it all back together.

The cam bearings did have some wear, so to be safe we replaced those.

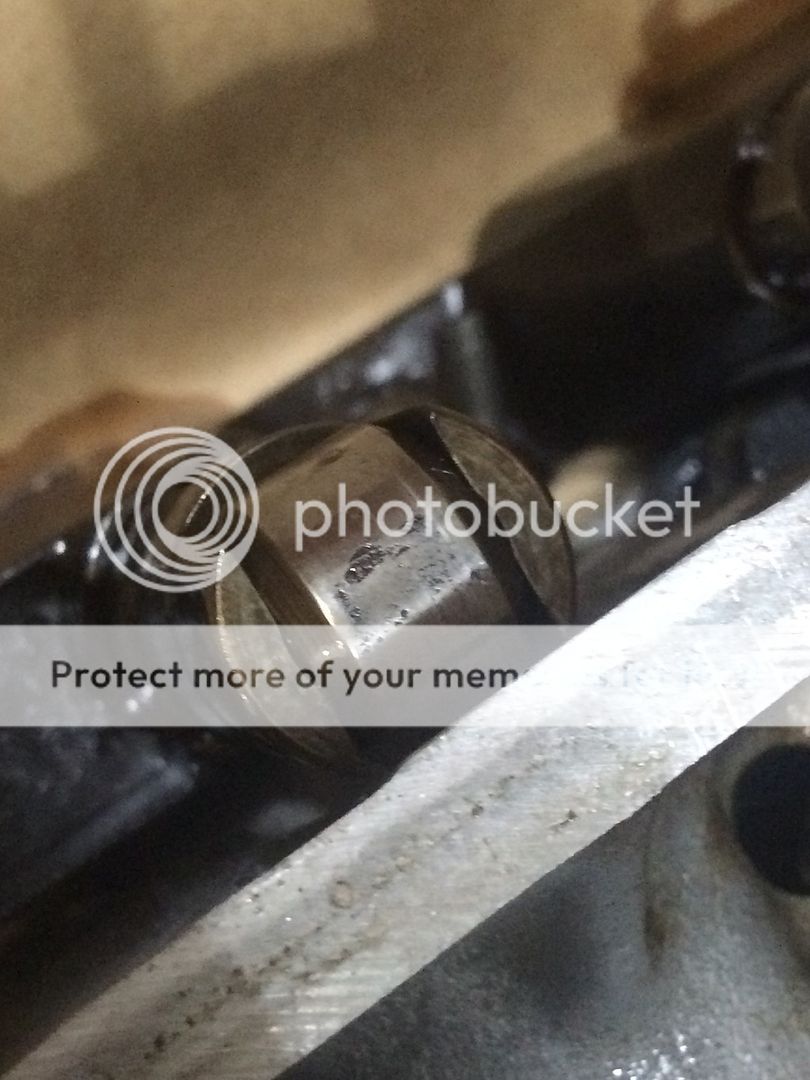

Worst one:

However, all the cam lobes and journals looked pretty good:

One lifter had some pitting, so I ordered a replacement for $7 from Amazon. That's and easy no brainer.

One thing I noticed was the cam retainer plate didn't have much of a sealing surface left on it. You can see where it connects the two main lifter galleys here:

Here is the sealing side. GM specification says if you cant feel the raised gasket material above the plate, replace it.

So I ordered a new one of those also, check out the difference! Definitely could have been losing some oil there...?

Anyway, got the cam back in, timing chain, front cover, new rear cover (old one had stripped both bolt holes) and oil pan installed last night.

I ordered some new head gaskets too, those show up today, so I should be able to get everything all buttoned back up tonight and back in the car tomorrow.

Wish me luck.

The cam bearings did have some wear, so to be safe we replaced those.

Worst one:

However, all the cam lobes and journals looked pretty good:

One lifter had some pitting, so I ordered a replacement for $7 from Amazon. That's and easy no brainer.

One thing I noticed was the cam retainer plate didn't have much of a sealing surface left on it. You can see where it connects the two main lifter galleys here:

Here is the sealing side. GM specification says if you cant feel the raised gasket material above the plate, replace it.

So I ordered a new one of those also, check out the difference! Definitely could have been losing some oil there...?

Anyway, got the cam back in, timing chain, front cover, new rear cover (old one had stripped both bolt holes) and oil pan installed last night.

I ordered some new head gaskets too, those show up today, so I should be able to get everything all buttoned back up tonight and back in the car tomorrow.

Wish me luck.

Man, you have been busy. I hope all goes well tomorrow.

Good luck.

So I had a little mishap last Friday while reassembling the top end.

I was reinstalling the cylinder heads and I was on the last full-size bolt of the last pass and it started feeling "spongy." I got nervous and told myself, OK just one more slow pull, and I just leave it at that. Torque setting on last pass is 75 ft. lbs....SNAP!

Oh man was I sick. It's just one think after another. I ended up moving on to the other head and it torqued down pretty easily. After some thinking (and drinking), I thought I might be able to back the broken piece out somehow. Luckily is wasn't bound up and after a little work with a flat head, I got my prize.

Broken bolt, you can see the threads on the upper part are tapered some where it started stretching.

Keep in mind these are ARP bolts, which I paid about $175 for. I called ARP and they mentioned a decent amount of broken bolt issues on the LS motors, both with their bolts and OEMs. Not sure the reason. They also said if it was a lot or heat issue, they would've gotten about 5,000 calls by now. So I guess they have some pretty large runs.

Their customer service was pretty good though, they said OK we will send you out a replacement and a shipping label for you to return the broken one so they can inspect it.

Unfortunately this is what showed up yesterday:

Can't do much with that.

In the mean time, I decided to reuse one of the OEM Torque to yield bolts. (GASP!)

It ended up torquing down fine. Luckily the location of this bolt allows be to swap it out by just pulling the valve cover, where the other bolts involve wither pulling the headers or the rocker arm assembly.

As seen here:

So the good news is that I'm up and running again, and everything checks out.

I'm planning on going by alignment shop tomorrow and getting front end taken care of.

Still not wanting to do any full throttle pulls, due to our tuning session getting cut short, but this thing has LOTS of power and sounds mean as hell. I'll try to get a video this weekend.

I was reinstalling the cylinder heads and I was on the last full-size bolt of the last pass and it started feeling "spongy." I got nervous and told myself, OK just one more slow pull, and I just leave it at that. Torque setting on last pass is 75 ft. lbs....SNAP!

Oh man was I sick. It's just one think after another. I ended up moving on to the other head and it torqued down pretty easily. After some thinking (and drinking), I thought I might be able to back the broken piece out somehow. Luckily is wasn't bound up and after a little work with a flat head, I got my prize.

Broken bolt, you can see the threads on the upper part are tapered some where it started stretching.

Keep in mind these are ARP bolts, which I paid about $175 for. I called ARP and they mentioned a decent amount of broken bolt issues on the LS motors, both with their bolts and OEMs. Not sure the reason. They also said if it was a lot or heat issue, they would've gotten about 5,000 calls by now. So I guess they have some pretty large runs.

Their customer service was pretty good though, they said OK we will send you out a replacement and a shipping label for you to return the broken one so they can inspect it.

Unfortunately this is what showed up yesterday:

Can't do much with that.

In the mean time, I decided to reuse one of the OEM Torque to yield bolts. (GASP!)

It ended up torquing down fine. Luckily the location of this bolt allows be to swap it out by just pulling the valve cover, where the other bolts involve wither pulling the headers or the rocker arm assembly.

As seen here:

So the good news is that I'm up and running again, and everything checks out.

I'm planning on going by alignment shop tomorrow and getting front end taken care of.

Still not wanting to do any full throttle pulls, due to our tuning session getting cut short, but this thing has LOTS of power and sounds mean as hell. I'll try to get a video this weekend.

quote:This meaning you've got good oil pressure now?

and everything checks out

Featured Stories

See All

A&M's growing 2026 class features pledges from across the country

by Ryan Brauninger

21:35

1d ago

5.5k

6:21

5h ago

768

Buzz Williams' Ags are proving why experience, continuity still matter

by Luke Evangelist