fossil

Glad you survived the crash, to live & tell these historical stories!

Glad you survived the crash, to live & tell these historical stories!

quote:

Hog killing day came on the first day in the Fall when morning temperatures were near freezing. This was an annual ritual in rural areas of West Texas up until about 1950 when refrigeration became available at "meat lockers" in town for storing meat. Hog killing day was an excused absence from rural area schools ... just as was cotton picking time in earlier times.

Before refrigeration, we killed, cut up and cured pork on the farm ... and stored it in dry boxes outside the house for a year. In companion processes on that day we rendered out the lard we would need for shortening for the year and made a years supply of laundry and bath soap that also served as a decent shampoo.

OK, I see I am losing some of you doubters already ... but it really happened this way, all in one day. (We did not invent the process ... it came from Tennessee, Missouri and other places long before we came along.)

The number of hogs killed depended on the family size ... a normal family of say four teenage boys would kill three. This would yield 12 hams and shoulders, 6 slabs of bacon, 6 pork tenderloins, 6 rib racks ... we did not keep internal organs like liver, kidneys, lungs, or the head or backbone but would give them to anyone who stopped by and asked for them.

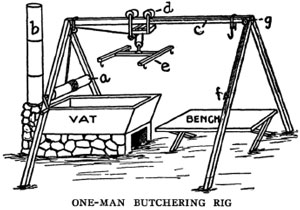

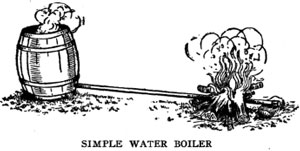

The day before we would round up all the tools, utensils, long table, etc needed for the job at hand. We would also rig up an A-frame with a block and tackle hoist. And dig a hole about 18 inches deep for the back end of a 55 gallon drum to lay in at about a 45 degree angle ... the open end of the barrel up. Then we would take a door off the barn and lay in front of the barrel for a clean place to scrape the hair off the hogs carcasses. (We did not skin hogs ... we needed clean hairless skin to make soap.) And we needed a cast iron wash pot to heat water in for dehairing the carcasses.

Work started at daybreak. A 250-300 pound hog would be singled out and shot between the eyes with a .22 rifle. We would immediately drag it out to the A-frame and hoist it up by its hind legs and cut the throat. After it bled out the carcass would be lowered and we would drag it to the 55 gallon drum. Hot water, steaming but not boiling, would be poured into the drum. The hog would be maneuvered into the drum and sloshed around a bit, then reverse end and done again to soften the hair ... then the carcass would pulled out onto the door for scraping. Long, sharp knives would scrape the hair off clean as a Gillette. Then back to the A-frame for gutting and splitting the carcass. The carcass was split on either side of the backbone with an axe. When this was done, if we had a couple of extra hands, the same process would begin on hog number two.

The split carcass would be carried to the back porch for the meat cutting. First, all the main parts would be cut out such as hams, shoulders, bacon slab, etc ... then those pieces were trimmed of all skin and fat. The trimmed fat and skin went into a tub and would later be cut up into about one inch chunks to be processed later into lard and soap. All meat trimmed off the primary cuts would go into another large bucket for sausage.

One person would then take the primary cuts to another work table and begin "salting." The sugar-cure salt we always used was a mixture of brown sugar and coarse salt. Each cut would be rubbed down good with the salt leaving a layer at least a quarter inch thick ... and a large hypodermic needle would be used to inject a dissolved portion of the curing mixture in around the joints of hams and shoulders. When we were done, those cuts were carried to the outside dry meat box for curing. The cure process took two weeks after which the cuts were removed from the box, the salt washed off in the cast iron pots, and the cuts returned to the box ... safely cured for year. (My grandfather did this with beef in earlier times but we never did.)

You can see this is quite a chore that gets very tedious if three hogs are killed. Usually it would take two or three men and three or four teenage boys going hard all day.

Usually sausage making was last on the meat cutting agenda. Trimming meat from the neck, jowells, backbone, etc was time consuming and you needed to see how much red meat you had to see how much fat you needed to get the right mix. Sausage spice mixture was a personal thing with the boss of the operation so everyone just stood back. A few days before, the mom of the bunch would have sewn sacks out of muslin for the sausages ... about two and a half inches diameter and 14 inches long. A hand grinder would be used and the ground pork would be hand stuffed into the sacks. After all hogs had been processed the sacks of sausage would be stacked up awaiting rendering out the lard.

Next, a wash pot would be set up with a good fire going under it. The fat trimmings including all attached skin would be dumped in. All that fat would soon melt into steaming hot grease (like you see when you fry bacon.) At this point you would need at least three or four four gallon tin buckets with lids. The first bucket would be filled with the sausage tubes standing upright. Hot grease would be dipped out of the pot and poured through a cheesecloth strainer over the sausage until they were covered, then that can was sealed. The sausage sealed this way would keep for months if stored in a cool place.

The rest of the hot lard would be dipped from the pot, strained through cheesecloth, and sealed in the four gallon cans ... to be used as shortening for the coming year. These also went into a cool place inside. What remained in the wash pot after all the lard was dipped out was "cracklings" ... the skin of the pigs that was cooked in the hot grease. The cracklings and any fat you may have chosen to leave in the pot were destined to become lye-soap.

To make soap, you just added five or six gallons of water to your pot and got your fire going again. When the water was steaming that was when you added a one-pound box of Lye (sodium hydroxide) to the mix. Lye dissolved the cracklings and fat, and in a short time the mix would begin to curdle in the pot. You kept stirring with a long wooden paddle until it got thick and you saw no more signs of cracklings. It was then done and time to cool. After the soap cooled in the pot it was a fairly solid mass about the consistancy of cheese. A long knife was used to cut this mass into about three inch squares, and then to maneuver the pieces out, to be cut again in to about 3X3X4 inch bars. And that, my friend, was Grandma's Lye Soap, Good For Everything in the Home.

Darn, I could have processed a hog in the time it took to type this. I apologize for the length of this post, but I think some of you might be interested in what your grandparents did on the farm to keep meat on the table ... in those days before refrigeration.