TexasAggie_02 said:

I know nothing about engineering, but I find it interesting that the horizontal tear along the top is smooth, and the vertical tear down the side is jagged.

Could it be possible that someone cut it along the top, and stress caused it to tear down the side?

Good observation, that the horizontal top "tear" is smooth, and the sides are jagged. What this means usually, is that there was a fatigue crack along the smooth part (due to high repeated tension), and then when the top section gave way the sides quickly broke which gave the jagged appearance. Following this logic, the bottom would also have the jagged appearance.

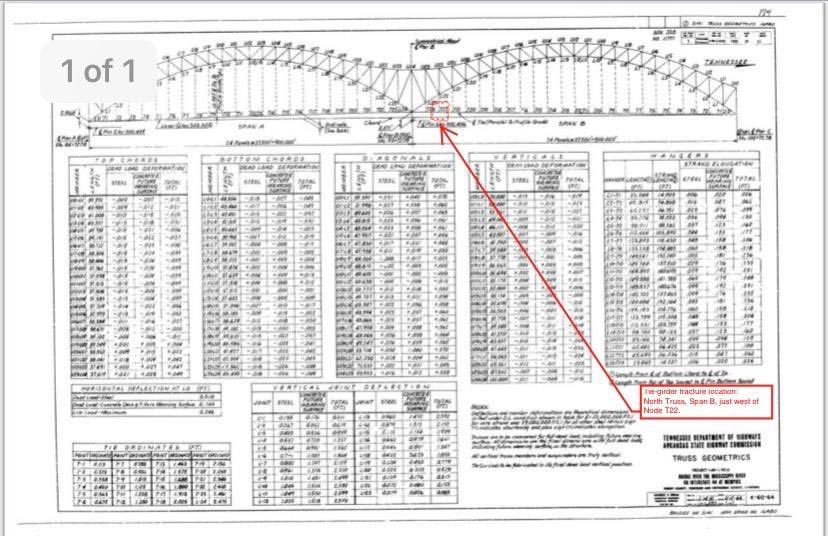

Thinking of the structure: This is a tied arch design. This bottom chord that broke is a tension member that ties ends of the bridge from spreading apart. The tension forces would be significant.

Given that this bottom chord also has moment fixity across the support points and at the vertical hanger points, it also is subjected to bending forces. The top side of the broken tubes would be a location of tension due to the bending moments, and that bending tension would add to the overall bridge action tension at the top side of these tubes. So it seems plausible that this beam was subjected to high repeated moments along with high tensions, eventually leading to a fatigue crack at top surface. Add in some originally locked in erection forces, with some corrosion perhaps, sure.

It will be interesting to see what the reports show.