I can't see that the throttle is the problem. I think with the throttle closed, it's getting way too much gas and flooding, and by manually opening it, it leans out enough to run.

If the governor is not working the throttle butterfly, that's a separate problem.

This has been annoying me, and I think some of these below have been mentioned before. I Googled a few sites for old tractors, and some of the same suggestions kept coming up, so, I'm going to spitball here, and sorry for the repeat and rehash of things you've done.

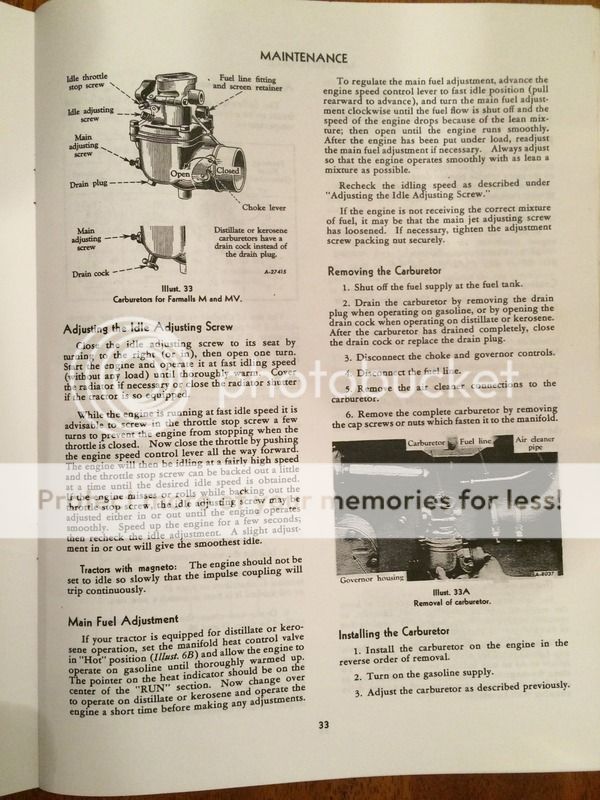

Speaking of butterflies, is the choke open and secure, where it does not flop closed when the engine starts?

Is the float floating? Leave it in a jar of gas overnight, see if it is still buoyant, and shake it and listen for gas inside the float.

Is the float binding? If the float pivot pin is worn, the float might be scraping the side of the bowl. My favorite cure for this I found online was to place a block of wood on the carb, then wack the wood with a hammer.

Is the fuel and the fuel passage in the carb absolutely clean? The least little grain of rust can hold the needle off the seat.

Is the seat (of needle.seat) firmly installed into the carb? This was a new one on me, but lots of folks claimed that seat needed to be firmly screwed in, and some even planed the flange where the seat installed, claiming it had warped. I seem to recall the seat had a gasket, is it there? And some folks added gasket sealer to it.

One other trick I saw mentioned, was to "seat" the needle. If the needle has a neoprene end that fits the seat, some of the old guys claimed you ought to tap the needle lightly into the seat to "set" the end of the needle to conform with the seat.

quote:

Better yet I might fill the bowl and then just disconnect the fuel line entirely.

Is there not a shut off valve under the tank? The Deeres had those, lots of folks killed the tractor at night by starving it of gas. I do that now, just to keep stale gas from gumming up the carb.

Good luck, and congrats on the coming little one.