So, found a plan on line that seems good enough.

However, for an 8'x8' shed on a concrete foundation, I'm thinking that the "studs" every 16" is a little overkill for structural stability.

My thinking (which may be way off is I could reduce the number of studs on this by some (to save money and effort). But I'm computer science and not civil engineering

Anyone got practical experience/suggestion.

32" might be too much by I figure I could space these out to remove at least 2 of the two studs

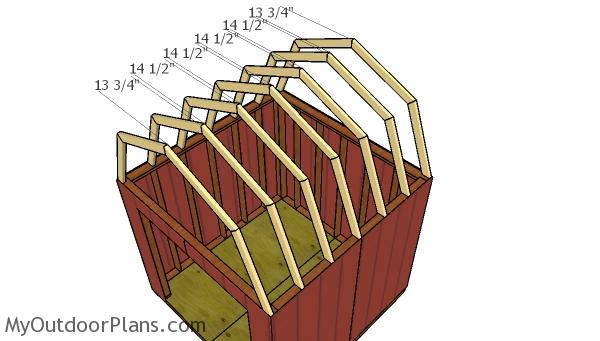

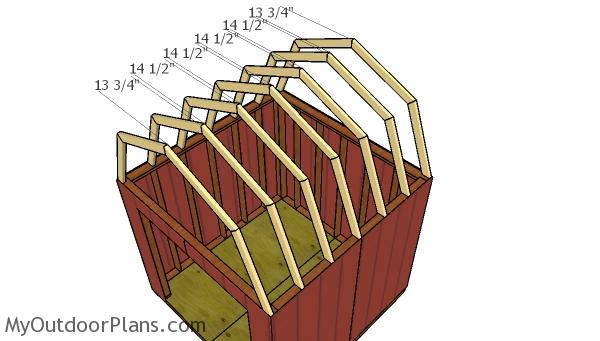

Here's a pic of the shed and number of studs.

However, for an 8'x8' shed on a concrete foundation, I'm thinking that the "studs" every 16" is a little overkill for structural stability.

My thinking (which may be way off is I could reduce the number of studs on this by some (to save money and effort). But I'm computer science and not civil engineering

Anyone got practical experience/suggestion.

32" might be too much by I figure I could space these out to remove at least 2 of the two studs

Here's a pic of the shed and number of studs.