Post Reply

1 of 1

What Catag does on his day off...

3,221 Views |

30 Replies |

Last: 13 yr ago by dubi

I did drive this guy from Bryan to Nacogdoches when I worked for the dealer in Bryan...never again.

6620?

HAH!

I roll on a Turbo 7720.

HAH!

I roll on a Turbo 7720.

awesome

but, isn't that the left break she is stepping on when the lyrics say 'pressin the gas'?

but, isn't that the left break she is stepping on when the lyrics say 'pressin the gas'?

Yep 07. Hydrostat, so no clutch. Throttle is on right side of seat. Only two pedals on the floor are left and right brakes.

Don't know how many times I've jumped off and on running combines. If you're switching drivers, the guy getting off holds the wheel and moves as far forward and out as he can, while the relief driver slides in behind and under.

Always keep the combines rolling....

Don't know how many times I've jumped off and on running combines. If you're switching drivers, the guy getting off holds the wheel and moves as far forward and out as he can, while the relief driver slides in behind and under.

Always keep the combines rolling....

Can someone enlighten a city boy as to what a combine actually does?

.....and no I'm not kidding

[This message has been edited by big ben (edited 8/24/2011 10:40p).]

.....and no I'm not kidding

[This message has been edited by big ben (edited 8/24/2011 10:40p).]

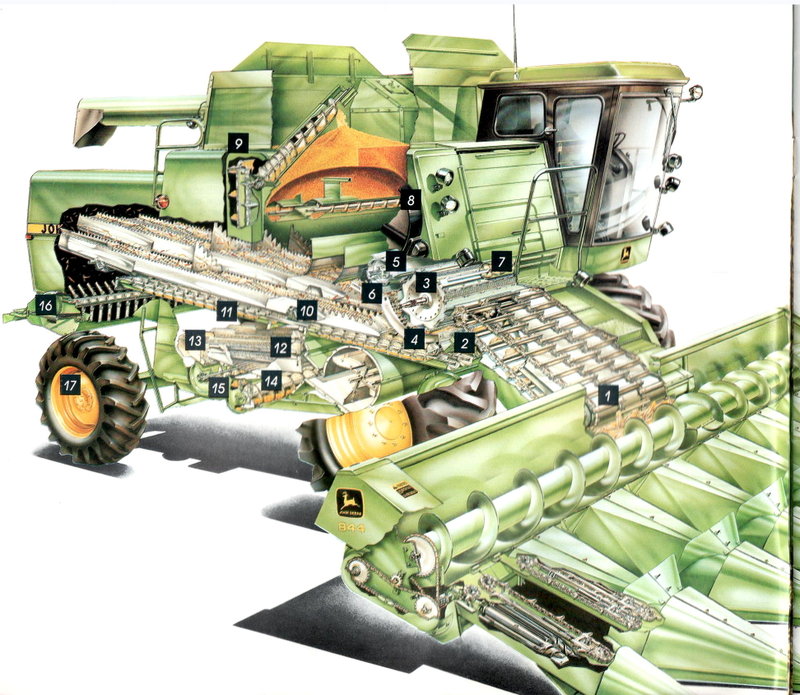

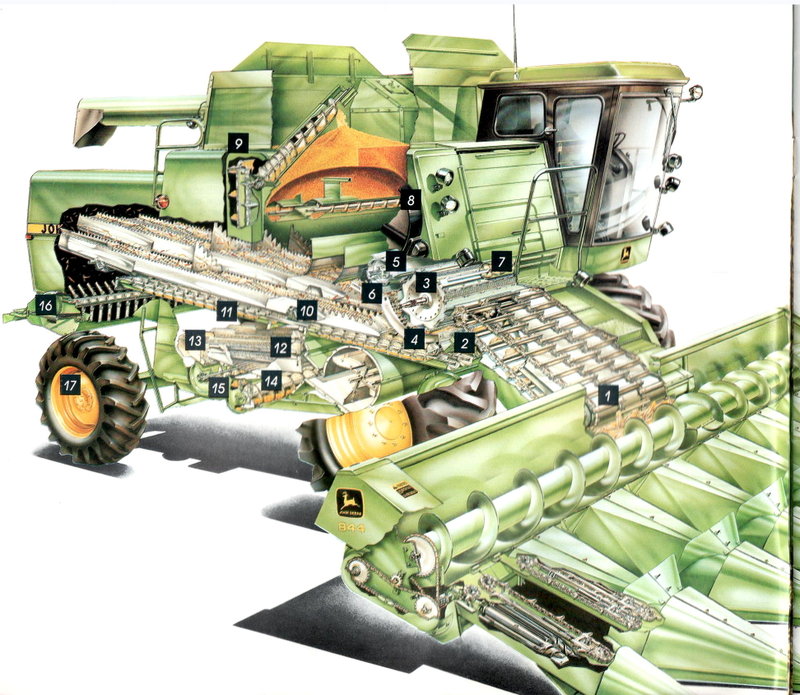

I don't have a video, but I have a cool photo

IMG_7357 by CHS Girls Soccer, on Flickr

[This message has been edited by CanyonAg77 (edited 8/24/2011 10:44p).]

IMG_7357 by CHS Girls Soccer, on Flickr

[This message has been edited by CanyonAg77 (edited 8/24/2011 10:44p).]

Big ben,

Much too long answer follows:

Back in the day (pre-WWII) there were two machines. One cut a grain crop down and tied it into bundles of stalk, head and grain together.

Those were often stacked to dry in the little stacks (shocks) you see on Thanksgiving cards.

Then they were hauled to a stationary thrasher. The thrasher separated the grain from the stalk and the head, used air to blow the chaff away and put the grain through sieves and into a bin.

When engines and running gear got big enough, the reaping and thrashing machines were combined into one machine that did both jobs at once.

So shorter answer: It cuts the grain plant and takes in the stalk and the head with grain.

It runs them through a "cylinder and concave" that rubs the grain out of the head.

Stalks and big pieces of unwanted material go up to "straw walkers" that move it to the rear and out, while sieving out any grain that went with the straw.

Grain, chaff and small debris go across cleaning screens that sieve out larger debris and let the heavier grain fall through. Air is blown up through these screens to blow off chaff and other light debris.

Clean grain is collected and augured into a bin. When the bin is full, it is augured into a waiting truck or "auger wagon" to head to market.

Much too long answer follows:

Back in the day (pre-WWII) there were two machines. One cut a grain crop down and tied it into bundles of stalk, head and grain together.

Those were often stacked to dry in the little stacks (shocks) you see on Thanksgiving cards.

Then they were hauled to a stationary thrasher. The thrasher separated the grain from the stalk and the head, used air to blow the chaff away and put the grain through sieves and into a bin.

When engines and running gear got big enough, the reaping and thrashing machines were combined into one machine that did both jobs at once.

So shorter answer: It cuts the grain plant and takes in the stalk and the head with grain.

It runs them through a "cylinder and concave" that rubs the grain out of the head.

Stalks and big pieces of unwanted material go up to "straw walkers" that move it to the rear and out, while sieving out any grain that went with the straw.

Grain, chaff and small debris go across cleaning screens that sieve out larger debris and let the heavier grain fall through. Air is blown up through these screens to blow off chaff and other light debris.

Clean grain is collected and augured into a bin. When the bin is full, it is augured into a waiting truck or "auger wagon" to head to market.

Thanks Canyon

Cutaway of a combine of the same vintage as the OP video.

Here's a couple of videos. The first is in German, but it shows some pretty good shots of a modern Deere machine in action. It includes some cutaway views of the insides. The German farmer looks positively orgasmic about the combine, as if he is imagining how grandad could have used it on Jews.

http://www.youtube.com/watch?v=RGw_XpwegrM

The next is a computer graphic of a CAT combine and its insides.

http://www.youtube.com/watch?v=GrxeFXM2jWE&feature=player_detailpage

http://www.youtube.com/watch?v=RGw_XpwegrM

The next is a computer graphic of a CAT combine and its insides.

http://www.youtube.com/watch?v=GrxeFXM2jWE&feature=player_detailpage

Canyon, do most large operations own their combine or do they contract the work? Coming from the earthmoving/mining industry it is always hard for me to wrap my mind around a combine being so expensive and then being parked most of the year.

Canyon ... Catag's dad has the first photo (B&W) version. Has a tractor hitch on it.

Wildcat, it all depends. Fewer and fewer own their own machine. New ones run $250,000 or better and it takes trucks, auger wagons, and a lot of labor to support them. Operations run the gamut from small guys like me who own 30 to 40 year old machines and limp them along, to 2-3 farmers sharing one machine, to huge operators who can justify the cost of their own machine because it allows them to get their crop harvested at peak quality and before the weather destroys the crop.

There certainly are custom operators. When I was a kid, my dad and his partner would do limited custom work for farmers in the area, and I still do a little, too. And I'm sure you've seen the real custom guys, the ones who start in South Texas and work their way to Canada each harvest. I've seen those guys with 5-10 combines, and the same number of tractors/auger wagons and semis in the caravan. They are going to be hurting this fall.

There certainly are custom operators. When I was a kid, my dad and his partner would do limited custom work for farmers in the area, and I still do a little, too. And I'm sure you've seen the real custom guys, the ones who start in South Texas and work their way to Canada each harvest. I've seen those guys with 5-10 combines, and the same number of tractors/auger wagons and semis in the caravan. They are going to be hurting this fall.

quote:

as if he is imagining how grandad could have used it on Jews

Thanks Canyon. If you need something for your combine to do in the off-season the guys at Top Gear have an idea for an emerging business.

Canyon .. just checked it out. It's a John Deere.

Safety was no concern back then.

Safety was no concern back then.

POSER!!!!

If he wants to impress anyone, he needs to upgrade to a 9870STS with a 40' draper head.

As soon as that straw walker crank goes out on that old 7700 it will be ready for the combine demo derby.

If he wants to impress anyone, he needs to upgrade to a 9870STS with a 40' draper head.

As soon as that straw walker crank goes out on that old 7700 it will be ready for the combine demo derby.

Wildcat-

You may have seen my early post about something I saw in Farm Show Magazine.

In every issue, there seems to be a story about someone who has taken an old combine and turned it into some other piece of farm machinery: snow blower (really) forklift, sprayer, etc.

Agronomist -

My dad collects antique tractors. Lots of exposed machinery on those. I used to gripe about all the shielding on modern tractors until I started going to antique tractor shows with dad. Amazing how many of those old guys were crippled, missing digits, missing limbs....

And I'm sure you know that the first tractors were all drawbar-pull type. The lift (three point hitch) did not come around for several years. Farmers had all their horse-drawn equipment, and the tractor had to be a direct replacement for the horse. One couldn't afford a new tractor and all new equipment to pull behind it.

Besides, if the tractor wouldn't start, you could always bring old Dobbin out of the back pasture and hook him back up to the equipment.

You may have seen my early post about something I saw in Farm Show Magazine.

In every issue, there seems to be a story about someone who has taken an old combine and turned it into some other piece of farm machinery: snow blower (really) forklift, sprayer, etc.

Agronomist -

My dad collects antique tractors. Lots of exposed machinery on those. I used to gripe about all the shielding on modern tractors until I started going to antique tractor shows with dad. Amazing how many of those old guys were crippled, missing digits, missing limbs....

And I'm sure you know that the first tractors were all drawbar-pull type. The lift (three point hitch) did not come around for several years. Farmers had all their horse-drawn equipment, and the tractor had to be a direct replacement for the horse. One couldn't afford a new tractor and all new equipment to pull behind it.

Besides, if the tractor wouldn't start, you could always bring old Dobbin out of the back pasture and hook him back up to the equipment.

quote:

The German farmer looks positively orgasmic about the combine, as if he is imagining how grandad could have used it on Jews.

Holy ****balls.

Have you watched the video?

Catch the look on the guy's face at the 0:23 mark!

[This message has been edited by CanyonAg77 (edited 8/25/2011 10:07a).]

Catch the look on the guy's face at the 0:23 mark!

[This message has been edited by CanyonAg77 (edited 8/25/2011 10:07a).]

Canyon...

Any idea how old this is. Only numbers found. "Thanks"

Steel wheel:

Any idea how old this is. Only numbers found. "Thanks"

Steel wheel:

Agronomist, sorry, not really my field, no pun intended. Only thing I found that might point you the right direction:

Forum discussion

Another source says Deere started making binders as far back as 1910.

And all those numbers are parts numbers for the individual pieces. I tried looking them up on the JD web page, but they are no longer valid part numbers.

[This message has been edited by CanyonAg77 (edited 8/25/2011 10:34a).]

Forum discussion

quote:

Parts Catalog PC-W8-(11-52) notes that the Light Running Grain Binder was built from 1923-1952 in 6, 8, and 10 ft sizes, and was available with pneumatic grain wheel with a cast-iron center and separate rim from 1936-1950 (from both the US and Welland-Canada works), and from 1950-52 a one-piece wheel was available from the Welland works.

A similar situation carried for the Main Wheel (bull wheel) - a 2-pc pneumatic wheel/tire was available from both US and Canada from 1938-1947, and from 1947-52 single wheel/rim was used, apparently from the Welland works. Not sure what the US Harvester works used during that time, but as I recall binder manufacturing moved to Welland sometime in the late 40's-early 50's. So this may help pin down your manufacturing date. A little more research may provide the tire sizes.

Another source says Deere started making binders as far back as 1910.

And all those numbers are parts numbers for the individual pieces. I tried looking them up on the JD web page, but they are no longer valid part numbers.

[This message has been edited by CanyonAg77 (edited 8/25/2011 10:34a).]

Thanks again Canyon.

Those numbers in the pictures look like John Deere part numbers. You might look for a casting number on a gearbox or motor block to figure out a date the part was cast.

Edit: I didn't see your earlier pictures. There obviously won't be a motor on that but you can check the frame and gearbox if one is there.

There was a pretty good article in last month's issue of Green Magazine on sickle bar cutters of that vintage.

[This message has been edited by EskimoJoe (edited 8/25/2011 10:58a).]

[This message has been edited by EskimoJoe (edited 8/25/2011 11:02a).]

Edit: I didn't see your earlier pictures. There obviously won't be a motor on that but you can check the frame and gearbox if one is there.

There was a pretty good article in last month's issue of Green Magazine on sickle bar cutters of that vintage.

[This message has been edited by EskimoJoe (edited 8/25/2011 10:58a).]

[This message has been edited by EskimoJoe (edited 8/25/2011 11:02a).]

"Thanks" EskimoJoe

quote:

The German farmer looks positively orgasmic about the combine

+1

@coopercuffe

Justin Tucker accused of multiple sexual harassments

in Billy Liucci's TexAgs Premium

50