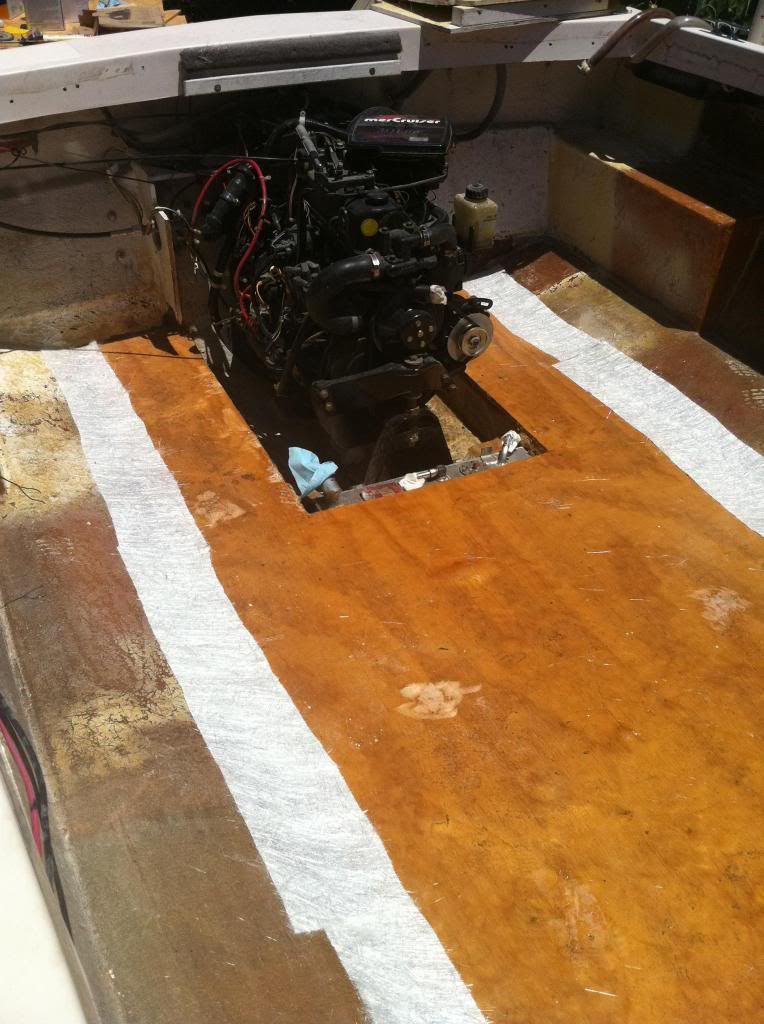

And here is the cured product.

Above, you can see the air pockets that would form as the fiberglass cured. No matter how hard I tried, I could not stop this from happening. I had a metal roller tool I used that was supposed to keep this from happening, and to an extent, it did. But there were several place where this occurred. In all these spots, I'd sand down the air bubble and add a fiberglass patch.

After all this was complete, I then put in A LOT of hours of sanding the entire surface down smooth.

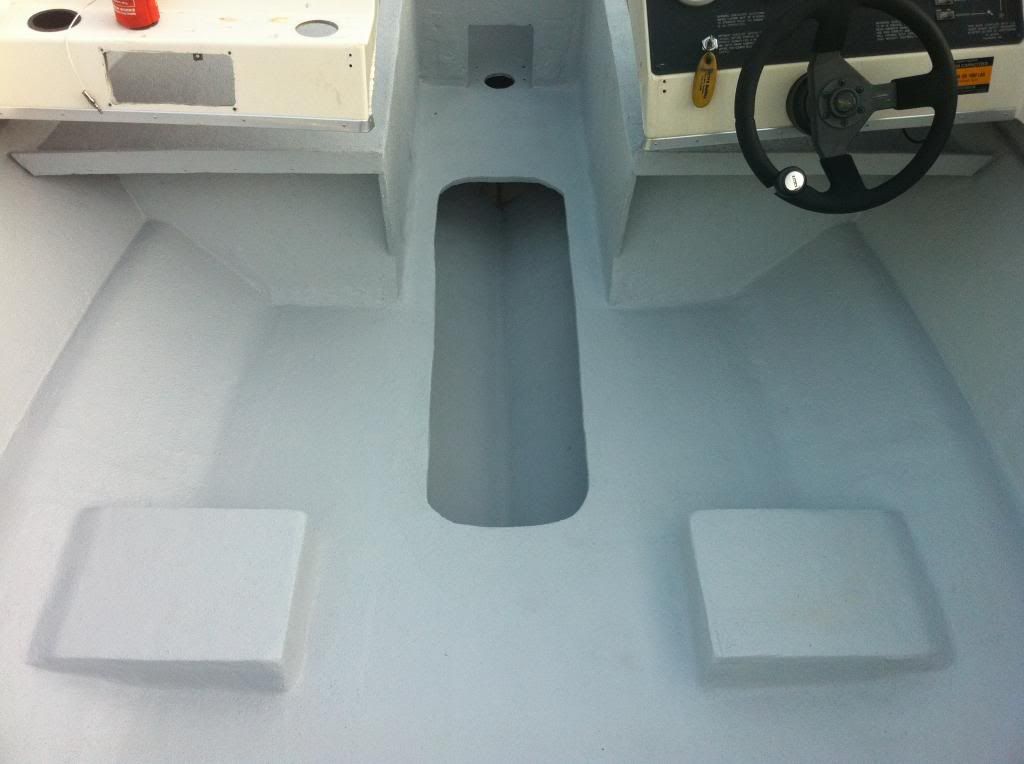

Switching gears a little bit, I mentioned how I cut out the back-to-back seating on each side and was going to replace with 2 captains chairs. Here are the new seat pedestals that I ended up using.

Also in that pic, notice that blue container. That stuff worked miracles when cleaning curing fiberlass off your skin. Once that resin starts to cure and gets on your skin, that s**t burns bad. Anyone whose ever done this sort of work can attest. But the hand cleaning sheets in that blue container cleaned the resin off instantly and effortlessly.

In order to mount those pedestals down, I was going to have to make some sort of wooden platform elevated from the bottom of the new deck to screw them down to. The centerline of each side console falls right on a grade break along the bottom of the hull.

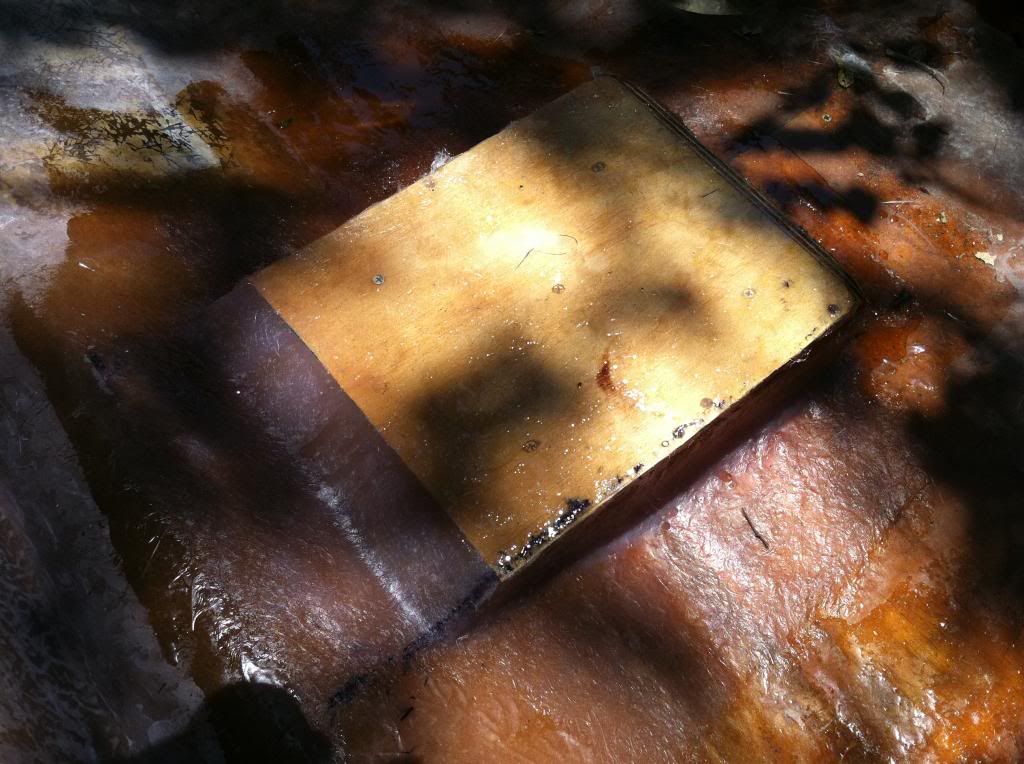

Here is the seat platforms I made to screw the aluminum pedestals to.

You can see in that pic what I mean about the grade break on the hull. To make that platform, I used cut out pieces of the same 1/2" foam board to make a template for each piece. I'd cut just a little bit off at a time until I got it to fit the contour of the hull correctly. Also seen in that pic is the cleaned up and sanded surface of the new deck after multiple layers of fiberglass and resin.

Here is a couple more.

[This message has been edited by BurrOak (edited 5/16/2013 10:04p).]

[This message has been edited by BurrOak (edited 5/16/2013 10:34p).]