I went to my parent’s house this past weekend and helped my dad with a few chores. One was to help make some Gambrels/deer hanger for our hunting lease. First, my dad made a jig on a welding table and we heated and bent about a dozen 3/8” round bar. After they were all bent, we cut two cross pieces (21 ½” and 4”) to make it stiffer. I got in some good practice with the welder and torch and had a great time with my dad building all of them! Oh and I quickly found out that a grinder, wire brush, and paint are a welders best friend.

As you can see in the pictures, one side is bent almost in a full loop. Many of y’all may have had this same problem, but whenever we’re about done quartering our deer, one of the hindquarters always wants to slip off when you remove the opposite side! If you remove the hindquarter that is on the straight side first, it will allow the hindquarter on the looped side to drop, but not fall off!

Me welding on the cross pieces

All the ones that we made--came out to about $1.50 a piece!!

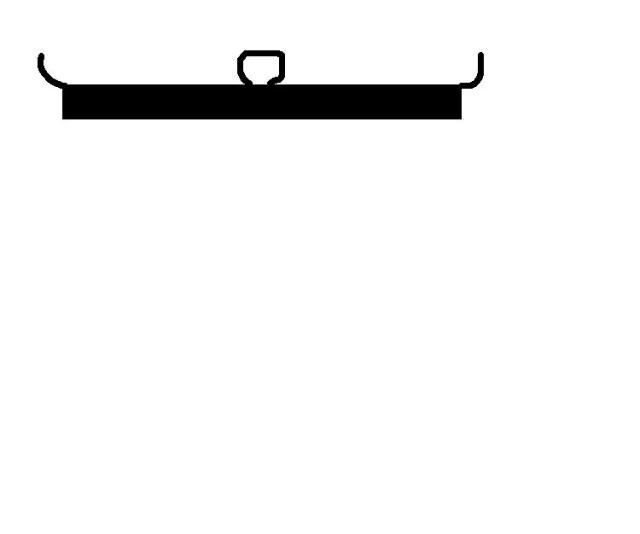

Finished product

And of course, the blueprints for the entire design! My dad always has everything perfectly measured out before we start any project. It makes it really nice once you get to work. You don’t have to do too much thinking once you get all the tools out….