Ok I'm ready to get more into water chemistry. What salts do y'all keep on hand? Should I just buy several of them and keep them around to build the profile I want from RO water?

Homebrew Board - Recipes

377,119 Views |

3346 Replies |

Last: 21 hrs ago by swampstander

I keep gypsum and calcium chloride on hand and build from distilled. There is lots of research to be done, but I like to keep it simple and my beers turn out okay. Gypsum and calcium chloride are the two most important salts because they affect the most important mineral ppm in your water profile. Bru'n water is a little finicky in my experience but with some tweaking and watching some tutorials it will get the job done. I also have lactic acid on hand and have used it on occasion, but anecdotally haven't noticed a huge difference with that.

The water chemistry primer on HBT helped me get started and I took it a step further from there based on calculations I got from Bru'n water.

https://www.homebrewtalk.com/forum/threads/a-brewing-water-chemistry-primer.198460/

The water chemistry primer on HBT helped me get started and I took it a step further from there based on calculations I got from Bru'n water.

https://www.homebrewtalk.com/forum/threads/a-brewing-water-chemistry-primer.198460/

I keep gypsum, calcium chloride, chalk, and Epsom salt on hand. Also have tartaric acid and baking soda in pantry for pH adjustment.

Properly balancing minerals and monitoring mash pH has really helped me to get the flavors I'm looking for and improved my mash conversion.

Properly balancing minerals and monitoring mash pH has really helped me to get the flavors I'm looking for and improved my mash conversion.

Packaging the gose today was unmitigated disaster. Only got about 3 gallons and there's a good chance it's oxidized. What should have been 15 minutes ended up almost 3 hours. Dip tube kept getting clogged.

Yeast and beer everywhere. Guess I will be investing in a clear beer draft system for fermentation!

Yeast and beer everywhere. Guess I will be investing in a clear beer draft system for fermentation!

How do you transfer? Haven't had this issue with a siphon

I have gypsum and calcium chloride on hand plus tartaric acid and baking soda. Ordered some food grade epsom salt and phosphoric acid today.

Going to brew blonde ale again probably this week

Going to brew blonde ale again probably this week

I ferment in kegs and typically transfer via co2 to a purged and sanitized keg through the dip tube. Only today there was a lot more yeast than usual, possibly mixed with crushed berries and it was clogging the tube like crazy, until all of a sudden it wasn't.

There's an item called a sure screen that goes on the end of your dip tube to help prevent this kind of thing.

https://www.morebeer.com/products/racking-cane-filter.html

https://www.amazon.com/KegWorks-Homebrew-Hops-Filter-Screen/dp/B006FX4ZCK

https://www.morebeer.com/products/racking-cane-filter.html

https://www.amazon.com/KegWorks-Homebrew-Hops-Filter-Screen/dp/B006FX4ZCK

I want to chime in on the fridge discussion from last page;

I use an upright fridge all the time for fermenting (an old top freezer model). Yes the freezer becomes useless as far as a freezer is concerned. Plug the fridge into temp controller and it runs as needed to keep fridge box at desired temp.

To prevent short cycling, put your temp probe in a glass of water in the fridge. It changes temperature more slowly. OR, change the differential on your controller if it has that ability. In otherwords, don't set it to kick on 1 degree over your set temp, you can change it to like 3. The johnsons don't do this, they are set, but the rancos and others can.

As far as ambient temp being close to desired temp, that is not a problem at all, in fact it makes life easier. This was the case for my last beer, I wanted 65, and that's about what my basement was. Solution? Unplug fridge altogether and leave the fridge door open.

Ornlu, I think you have this backwards. It's not going to run more if your ambient temp is close to your set temp, the opposite is true. (just like your example of hot 105 degree garage). If ambient is say 67, and fridge is set to 63, then your fridge is losing heat VERY slowly, causing it to run less to keep 63. If ambient is same as the set temp, then theoretically it would never run. (see my example above.. just leave the door open)

I use an upright fridge all the time for fermenting (an old top freezer model). Yes the freezer becomes useless as far as a freezer is concerned. Plug the fridge into temp controller and it runs as needed to keep fridge box at desired temp.

To prevent short cycling, put your temp probe in a glass of water in the fridge. It changes temperature more slowly. OR, change the differential on your controller if it has that ability. In otherwords, don't set it to kick on 1 degree over your set temp, you can change it to like 3. The johnsons don't do this, they are set, but the rancos and others can.

As far as ambient temp being close to desired temp, that is not a problem at all, in fact it makes life easier. This was the case for my last beer, I wanted 65, and that's about what my basement was. Solution? Unplug fridge altogether and leave the fridge door open.

Ornlu, I think you have this backwards. It's not going to run more if your ambient temp is close to your set temp, the opposite is true. (just like your example of hot 105 degree garage). If ambient is say 67, and fridge is set to 63, then your fridge is losing heat VERY slowly, causing it to run less to keep 63. If ambient is same as the set temp, then theoretically it would never run. (see my example above.. just leave the door open)

Getting supplies for my first solo brew (I've joined others recently). After helping out with a few I already know that I am getting into this, so don't mind a little long-term planning.

I will for sure be starting extract, and want to start immediately on a propane burner rather than in a kitchen. What do y'all think of these for brewing?

https://austin.craigslist.org/for/6599265233.html

https://sanantonio.craigslist.org/for/6612576459.html

Also, I have a current $50 gift card to Cabela's. Looks like there's a few things I could get through them, any recs?

Thanks.

I will for sure be starting extract, and want to start immediately on a propane burner rather than in a kitchen. What do y'all think of these for brewing?

https://austin.craigslist.org/for/6599265233.html

https://sanantonio.craigslist.org/for/6612576459.html

Also, I have a current $50 gift card to Cabela's. Looks like there's a few things I could get through them, any recs?

Thanks.

Without a doubt the second one. It'll be much easier to use. It also helps if you elevate it so you can open the ball valve and drain directly into your fermenter. Just saves on lifting.

If you go full boil you will generally start with 6 gallons in the pot, leaving 2 gallons for headspace. You will probably have a boil over so keep that in mind in where you decide to brew. The trick is to watch it as it comes to a boil and be ready for the foam and turned the propane down.

You will need thick wall tubing with 1/2" ID for the ball valve to drain it to your fermenter or just let if fly and use a funnel to collect it, if using a carboy.

Lastly, if going full volume you'll need a wort chiller to get the temp down. I usually use an immersion chiller and hose water to get it down to 90-100 in the summer, then a recirculating ice system to get it below 70 to pitch ale yeast.

How do you plan to control fermentation temps?

If you go full boil you will generally start with 6 gallons in the pot, leaving 2 gallons for headspace. You will probably have a boil over so keep that in mind in where you decide to brew. The trick is to watch it as it comes to a boil and be ready for the foam and turned the propane down.

You will need thick wall tubing with 1/2" ID for the ball valve to drain it to your fermenter or just let if fly and use a funnel to collect it, if using a carboy.

Lastly, if going full volume you'll need a wort chiller to get the temp down. I usually use an immersion chiller and hose water to get it down to 90-100 in the summer, then a recirculating ice system to get it below 70 to pitch ale yeast.

How do you plan to control fermentation temps?

You definitely want a valve on your brew kettle (or any pot for that matter). Like Alaska said, put it up higher above your carboy/fermenter/whatever, so you can just gravity feed it in. I would boil on the ground, then chill, then lift up higher. (In other words, don't boil water off the ground unless the pot is substantially supported, and don't lift pots of boiling water)

Find an immersion chiller on CL or DIY with some copper tubing if you're handy.

You don't need the temp gauge on a brew kettle, but as you expand (the homebrewing hobby is in a continuous state of expansion), that could become your HLT or mash tun.

Find an immersion chiller on CL or DIY with some copper tubing if you're handy.

You don't need the temp gauge on a brew kettle, but as you expand (the homebrewing hobby is in a continuous state of expansion), that could become your HLT or mash tun.

I'd use cider blocks to raise it up, needs to be very sturdy, and important if you whirpool the hops at the end to get them to settle into a cone.

Biggest steps are end boil, chill down quickly to pitch yeast, then maintain temps so you get a good product at the end. Cheapest solution is a swamp chiller. Better is a small fridge.

It's a fun hobby.

Biggest steps are end boil, chill down quickly to pitch yeast, then maintain temps so you get a good product at the end. Cheapest solution is a swamp chiller. Better is a small fridge.

It's a fun hobby.

Yes, I plan to control the fermentation temps.

Speaking of which, looking at fridges now. Plan to buy used and retrofit controller to it.Chipotlemonger said:

Yes, I plan to control the fermentation temps.

Never have bought a fridge before. There's one in the family that I am seeing about using for taps and freezing hops and what not. What base requirements do I need for fermentation fridge? Initially I think I'd be fermenting just one 5 gallon batch at a time, maybe down the line it would be more though or a larger batch itself in 2 containers.

The only requirements are space and ability to cool hah.

Temp controller is set at 60-75 depending on the ale, and 50s depending on the lager, so that's easy for fridges since they are designed to go to 30s. Your freezer won't freeze while it's set to those temps, so don't have anything in freezer that you can't move easily to another freezer during fermentation. I also wouldn't have 1 fridge that has kegs/taps that I also use for fermenting, unless you don't mind going without your taps for 2-3 during fermentation. You need a dedicated fermentation fridge.

I have a small 15cuft fridge in basement that I use for 5 gallon batches, or a lager in the summer, since my conical can't cool that low while in the garage, it works great.

Temp controller is set at 60-75 depending on the ale, and 50s depending on the lager, so that's easy for fridges since they are designed to go to 30s. Your freezer won't freeze while it's set to those temps, so don't have anything in freezer that you can't move easily to another freezer during fermentation. I also wouldn't have 1 fridge that has kegs/taps that I also use for fermenting, unless you don't mind going without your taps for 2-3 during fermentation. You need a dedicated fermentation fridge.

I have a small 15cuft fridge in basement that I use for 5 gallon batches, or a lager in the summer, since my conical can't cool that low while in the garage, it works great.

Currently I have a small fridge, but it has one of those floating freezer sections inside and the big stair in the middle of it to go around the compressor/equipment underneath it.

I do plan on having separate fridges for fermentation and kegs. Think I'll keep the mini fridge as just that.

I do plan on having separate fridges for fermentation and kegs. Think I'll keep the mini fridge as just that.

I'll add, when I first dove into real temp control, I used a small chest freezer. The ones that are like 5 cuft. They take up very little footprint (about 2x2), and you can typically fit 2 carboys in there. (One on the floor and one on the hump)

I got it on CL for all of like $30. Get a temp controller and you're good.

I got it on CL for all of like $30. Get a temp controller and you're good.

Interesting. I didn't think my mini fridge would be near big enough for a 5 gal fermentation. Was yours without a freezer or that inside shelf?

That's the problem with most smaller fridges.For mine, I had to double up the bottom shelf to support weight of carboy, and it's just big enough inside to have carboy plus blow off tube. Your typical dorm size fridge will not be big enough. Like I said mine is like a 12-15cuft model:Chipotlemonger said:

Currently I have a small fridge, but it has one of those floating freezer sections inside and the big stair in the middle of it to go around the compressor/equipment underneath it.

I do plan on having separate fridges for fermentation and kegs. Think I'll keep the mini fridge as just that.

Took out that top beer shelf, put in on top of that bottom crisper deal, and it has just enough height.

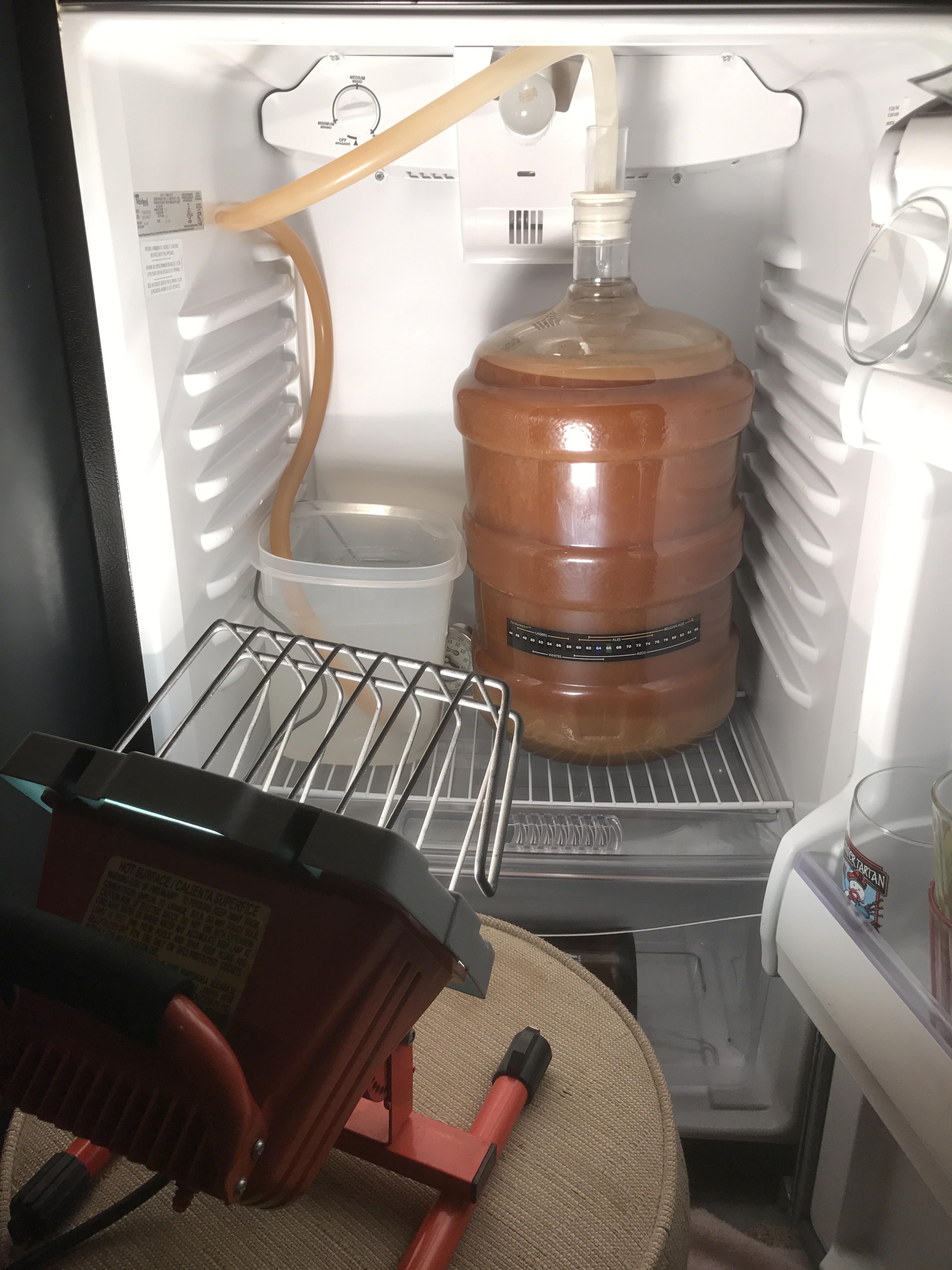

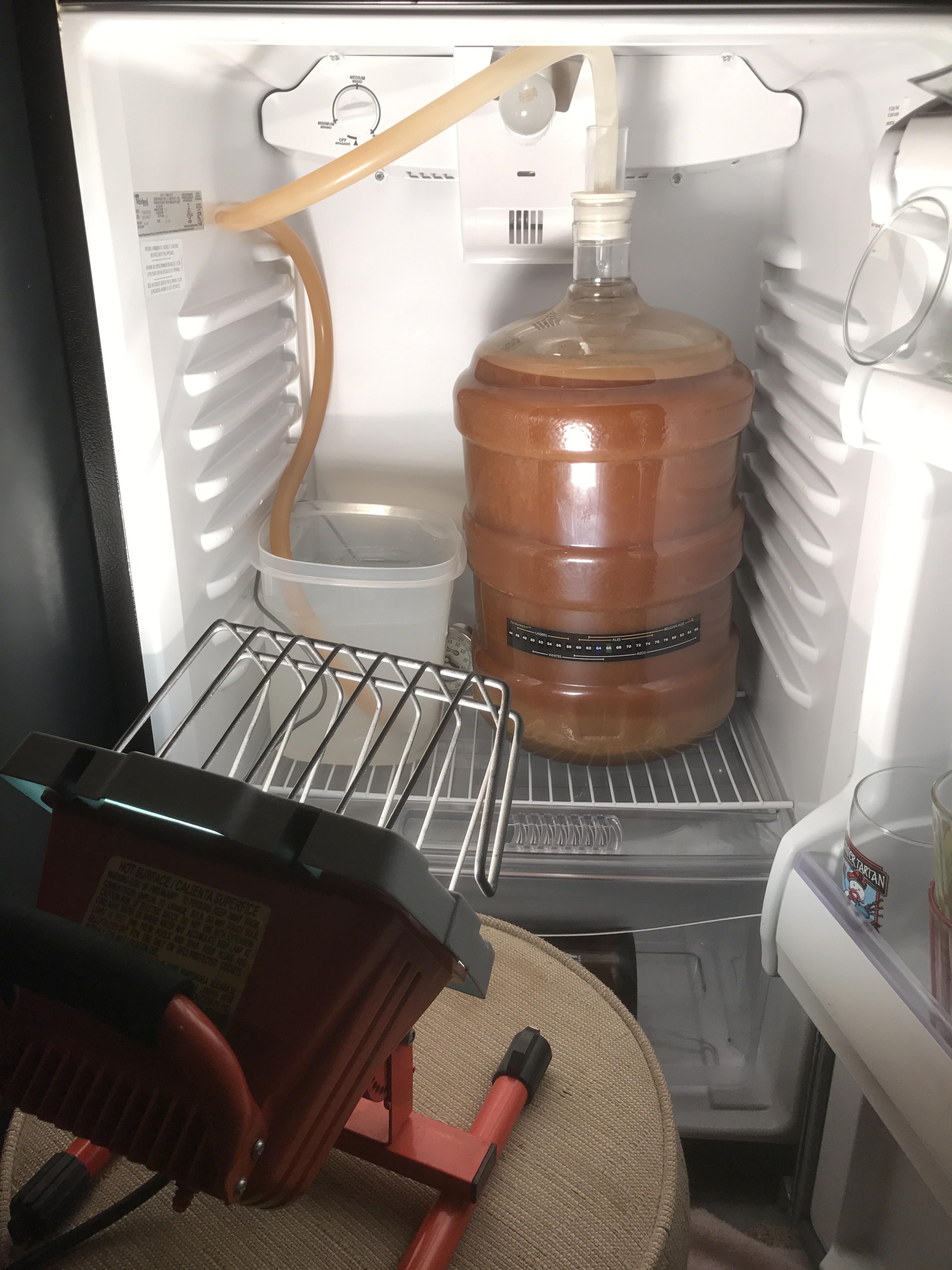

But previously in TX, I had this. Held two carboys, but only after I put the collar on there for the extra headroom for blow off.

Here it is in action. I put the light on it to speed up the heating from 50s to diacetyl rest temp.

A dorm sized fridge works well for some carboys, but you have to remove the door shelves. And it helps a ton of it has a back cooling plate and not the mini freezer unit.

Just finished brewing my blonde ale again for a customer event. After 3 all grain brews I'm consistently getting 60% efficiency from my setup. I feel like it should be higher. I am a little frustrated by it. Have a 55 qt igloo with a bazooka screen for a manifold. Haven't had anything get stuck but maybe that's my problem? I've been double batch sparging around 170 degrees. Any ideas?

Who's crushing your grain? It's that or your measurements are off. Check your hydrometers with distilled water.

I usually empty mash, fill up/stir/empty, and then again fill up/stir/empty.. then I just boil an hour or so before my first hop addition.

Can you do another rinse and then boil longer? Are you ending up with proper amount of wort for fermenter?

Can you do another rinse and then boil longer? Are you ending up with proper amount of wort for fermenter?

How are you calculating your efficiency? Post an example.

How are you vourloufing? Do you think it's channeling?

When I batch sparged I'd place a piece of aluminum foil on top of the grain bed and pour into that, then remove it so the wort sat on top of the bed. Then pull a gallon, place foil, return, remove etc.... My batch sparge efficiency was a solid 65%. Sucked but was stable.

When I batch sparged I'd place a piece of aluminum foil on top of the grain bed and pour into that, then remove it so the wort sat on top of the bed. Then pull a gallon, place foil, return, remove etc.... My batch sparge efficiency was a solid 65%. Sucked but was stable.

I need to check my hygrometer. I order my grains crushed from whoever I buy it from, usually Austin's home brew, sometimes Northern brewer or Defalcos. I calculate it using brewers friend, they take the grain bill and then based on volume and gravity will calculate how much of the available sugar you get out. I don't think it's channeling, it's a rectangle cooler. Process is

Preheat while mash water is getting to temp.

Drain water, fill with grain, add mash water, stir thoroughly

Let sit 15-20 minutes and stir x2

Recirculate at 5-10 minutes left to get grain out, stir and circulate one more time

Drain as much as possible

Add first sparge, stir, let sit 10 minutes

Drain as much as possible

Add second sparge, don't stir, let sit 10 minutes and drain drain drain. Will tip cooler over as much as possible to move grain around and prevent channeling and keep draining and holding it at an angle until there is basically no water left coming out. Then go on with boil as usual.

My total water ending up in fermenter is right at 5.25-5.3 gallons which gives me almost exactly 5 gallons of finished product. So I think as far as that goes that is right. Mash at 1.33qt/pound of grain. Temps look good

Preheat while mash water is getting to temp.

Drain water, fill with grain, add mash water, stir thoroughly

Let sit 15-20 minutes and stir x2

Recirculate at 5-10 minutes left to get grain out, stir and circulate one more time

Drain as much as possible

Add first sparge, stir, let sit 10 minutes

Drain as much as possible

Add second sparge, don't stir, let sit 10 minutes and drain drain drain. Will tip cooler over as much as possible to move grain around and prevent channeling and keep draining and holding it at an angle until there is basically no water left coming out. Then go on with boil as usual.

My total water ending up in fermenter is right at 5.25-5.3 gallons which gives me almost exactly 5 gallons of finished product. So I think as far as that goes that is right. Mash at 1.33qt/pound of grain. Temps look good

I do 60 mins (minimum) for that step. Sometimes 90 if it's a big grain bill. This is the "conversion", and it should be the bulk of the mash step. Certainly longer than 30 minutes. Buy some tincture of iodine and check for starch conversion at the end of this step.Seven said:

I need to check my hygrometer. I order my grains crushed from whoever I buy it from, usually Austin's home brew, sometimes Northern brewer or Defalcos. I calculate it using brewers friend, they take the grain bill and then based on volume and gravity will calculate how much of the available sugar you get out. I don't think it's channeling, it's a rectangle cooler. Process is

Preheat while mash water is getting to temp.

Drain water, fill with grain, add mash water, stir thoroughly

Let sit 15-20 minutes and stir x2

Recirculate at 5-10 minutes left to get grain out, stir and circulate one more time

Drain as much as possible

Add first sparge, stir, let sit 10 minutes

Drain as much as possible

Add second sparge, don't stir, let sit 10 minutes and drain drain drain. Will tip cooler over as much as possible to move grain around and prevent channeling and keep draining and holding it at an angle until there is basically no water left coming out. Then go on with boil as usual.

My total water ending up in fermenter is right at 5.25-5.3 gallons which gives me almost exactly 5 gallons of finished product. So I think as far as that goes that is right. Mash at 1.33qt/pound of grain. Temps look good

I also grind my own grain, which is set a little finer than AHB's mill.

Should have clarified. I let it mash for 60 minutes but stir it every 15-20 minutes

I'm not sure on the error then. I also use a square (coleman) cooler, with a piece of braided stainless steel for a screen. I only sparge once. My procedure is more like:

I'm consistently over 70%, usually in the 74-78% range, with a career-high of 82%.

That all said: It doesn't sound like my process is much different than yours.

- Don't preheat mashtun, just over heat the water by a few degrees. Usually mash between 154 and 149.

- Dough in thick, like 1.25 lb/qt.

- Mash for 60+ mins, stirring every 10-15 mins and checking for conversion before running the wort out.

- At wort runnout, I gravity flow approx 1/2 gallon from the mashtun into a picture and then pout that back into the mashtun (to let grain bed set up).

- Gravity flow the wort into the boil kettle. Let ALL of it drain out (takes 15+ minutes).

- Stir sparge water in, stirring very well. Let it sit for about 5 minutes, and then use picture to recycle a bit to get grain bed to reset. Runoff to kettle.

- After maybe 10 minutes, start boil kettle to heat. Continue to collect sparge runnings until the boil starts.

- Boil until I hit my pre-boil gravity before adding hops. Usually 15-60 minutes.

I'm consistently over 70%, usually in the 74-78% range, with a career-high of 82%.

That all said: It doesn't sound like my process is much different than yours.

That is essentially the same thing I do except I'm a little thinner. How do you determine what your preboil gravity should be? I just collect everything and as soon as I start boiling I'll start the timer and add the hops accordingly. Generally start with 6.5-7 gallons in the pot and end with 5.3ish and 5.25ish in the fermenter. I need to keep some light DME around to kick numbers up some but my final ABV has been great on everything so far. I won't take a gravity reading until it's 80 degrees and I'm about to add the yeast.

My pot & kettle boil off between 1.1 gals/hour (at a low to moderate boil) and 1.8 gals/hour (at a roaring boil). If I want to have 10.75 gallons in the fermenter, and I'll lose another 0.5 or so to the coil & kettle. So I want my post-boil volume to be 11.25 gals. If I'm boiling 60 minutes, and figure I'll do so hot (depending on recipe & gravity targets), then pre-boil volume should be about 12.75 gals.

If I'm a point or two low (1.052 instead of 1.054) for OG, oh well. Same for overs. I do start to get annoyed when I'm more than 0.05 off though.

If I'm a point or two low (1.052 instead of 1.054) for OG, oh well. Same for overs. I do start to get annoyed when I'm more than 0.05 off though.

sg is linear.Seven said:

How do you determine what your preboil gravity should be?.

X points in 10 gallons is 2x points in 5 gallons if you boil it down (assuming not adding or subtracting sugars in the process)

Or just use software. Beersmith tells me initial boil and final boil gravities.

I also assume a half gallon loss in chiller/hoses, and half gallon loss in fermenter, so I shoot for 11 gallons to fill two kegs.

Then 1-2 gallon loss depending on boil time. So I start with 12 or 13 gallons.

Featured Stories

See All

18:03

14m ago

350

REGISTER NOW: Preseason Kickoff 2024 with Coach Mike Elko

by Brandon Jones

Around the SEC: Recruiting News & Trends

by Jason Howell

8:09

6m ago

135