All of the OEM outlets in the house have the wires inserted directly into the holes in the back of them, instead of clamped down with the screw. I hope you can visualize what I am saying as I forgot to take a picture. I like this, makes life easier, but it seems every new outlet I find, the holes on the back are smaller than the wire guage used in my house. Is this normal? Seems very odd that the new equipment wouldn't be compatible. I'd really like to avoid having to spend 4x as much to find something compatible. I can post a photo later if necessary. Thanks for the info.

Changing Electrical Outlets Question

2,991 Views |

34 Replies |

Last: 2 yr ago by Jason_InfinityRoofer

These push-in connectors are probably 14 awg on new outlets. Many electricians are not fans of these connectors. Most of the push-in connectors use a friction mechanism to hold the wires in, but I think GFCI outlets have screw clamps on the push-in connectors.

I would recommend the side screw clamps even though they take a bit longer.

I would recommend the side screw clamps even though they take a bit longer.

They are such a pain in the ass with the heavy Guage wire in the house and the small outlet boxes. Thanks.

My '88 build is the same way. It is a bit of a pain at first but after doing a couple the conversion goes pretty quick.

I always just cut them off and strip them, I've never had luck getting the wires to release from the current outlets.

Yea of course. Always a game time decision.

GrimesCoAg95 said:

These push-in connectors are probably 14 awg on new outlets. Many electricians are not fans of these connectors. Most of the push-in connectors use a friction mechanism to hold the wires in, but I think GFCI outlets have screw clamps on the push-in connectors.

I would recommend the side screw clamps even though they take a bit longer.

That. Stab ins are 5hit. Think of holding a piece of bare wire between the thin tips of tweezers versus screwing it down. You have much better and more solid contact with the screw. I've got a receptacle laying around someplace I took out of my parents' place that started to melt from a fake fireplace running for a while. The "tweezer tips" inside the device overheated.

Roger on all, will take the time to screw em down. Hope I can find some with the decent sandwich connectors instead of just the screw head.

The screw head will do just fine if you get solid contact. Find the sweet spot on a pair of needle nose pliers. Grab the wire and twist, and you will have the perfect hook to go under the screw. The hook should wrap clockwise around the screw such that when you tighten it, it's not trying to push the wire off. The hook should go 2/3 to 3/4 around the screw, but not overlap. And then like my dad always said, tighten that thing like it was the wheel on a train.

Bend the wires before you attach such that they will accordion their way back into the box. Pay attention to the bare part of the wire to where you aren't going to push it back across a terminal on the side. Sometimes helps to dry fit the receptacle in the box to see where you're gonna want the wires to end up. This is also where the screw rides king over the stab in. Stab ins have a bad habit of wanting to pop loose or spin when you push the device back into the box.

Bend the wires before you attach such that they will accordion their way back into the box. Pay attention to the bare part of the wire to where you aren't going to push it back across a terminal on the side. Sometimes helps to dry fit the receptacle in the box to see where you're gonna want the wires to end up. This is also where the screw rides king over the stab in. Stab ins have a bad habit of wanting to pop loose or spin when you push the device back into the box.

Yea fair enough on wanting to pop out. Shame on me for wanting the easy way. I reckon it will just take me a few extra minutes per. If I can deal with thr pain of a bathroom remodel I can deal with replacing some outlets.

I agree with everything UnderoosAg noted, especially regarding the stab-in connections being 5hit. I too have run across outlets that have overheated and melted due to the wires loosening up over time. Actually had an outlet catch fire due to the stab-ins.

Also, I recommend wrapping the outlets to cover the connections with electrical tape to minimize the possibility of making contact with the ground wires when inserting the outlets into the j-box. Also helps in the case of duplex switches and or outlets in j-boxes when one is on one circuit and the other is on another. It only took me one time to learn that lesson...

Also, I recommend wrapping the outlets to cover the connections with electrical tape to minimize the possibility of making contact with the ground wires when inserting the outlets into the j-box. Also helps in the case of duplex switches and or outlets in j-boxes when one is on one circuit and the other is on another. It only took me one time to learn that lesson...

Gary79Ag made a great point about taping the outlets. I always do that for GFCI outlets, or when I am putting any outlet into a metal box.

1/8 IN drill bit; problem solved

Always use the screw clamps. I prefer the screw clamps with a sub plate that is slotted to accept straight stripped wire. If that's not available on the outlet I'm working with, I use the wire stripper the way they were designed and bend a loop and squeeze the loop down once it's around the screw.

For all of my new work, I've been using the Leviton Commercial grade 20a outlets from Home Depot. They have the setup you referenced and I like the versatility. I find them to be superior to most others I've found. Sometimes they are better priced at my supplier but not usually. Anyway, they have a super clamp setup that I like quite a bit. Plus they are just nice feeling solid outlets. When I installed and wired my 100a sub panel to my new shop, I installed these outlets and they perform as well today as when I installed them. They hold cords better and seem to hold up to heavy use.

screwheads are actually really easy if you just learn to do it right. Throw the above needle nose plier tip out the window and use the tip about using the correct tool, your wire strippers. They have a hole in the ends, it's used to do as shown above.Sea Speed said:

Roger on all, will take the time to screw em down. Hope I can find some with the decent sandwich connectors instead of just the screw head.

But do it a bit longer than that. Make a taller U, so when you place it around the screw, you then use tweezer part of strippers to make a shape similar to that of the breast cancer awareness ribbon. Then tighten the screw and snip off of you have too much excess. A few times practice and it becomes very easy.

Also 2nd to only using commercial grade 20 amp with clamps. Much better performance if you're not used to getting the loop the right size and pushing out from under the screw. The biggest factor is the tension that they put on the plug.

On the back of the outlet is a strip gauge.

If you can get the wire out from under the spring type it should go directly into the clamp type saving time.

And remember "Black is brass, white is bright"

On the back of the outlet is a strip gauge.

If you can get the wire out from under the spring type it should go directly into the clamp type saving time.

And remember "Black is brass, white is bright"

tu- DDU * where NFL Dreams go to Die U

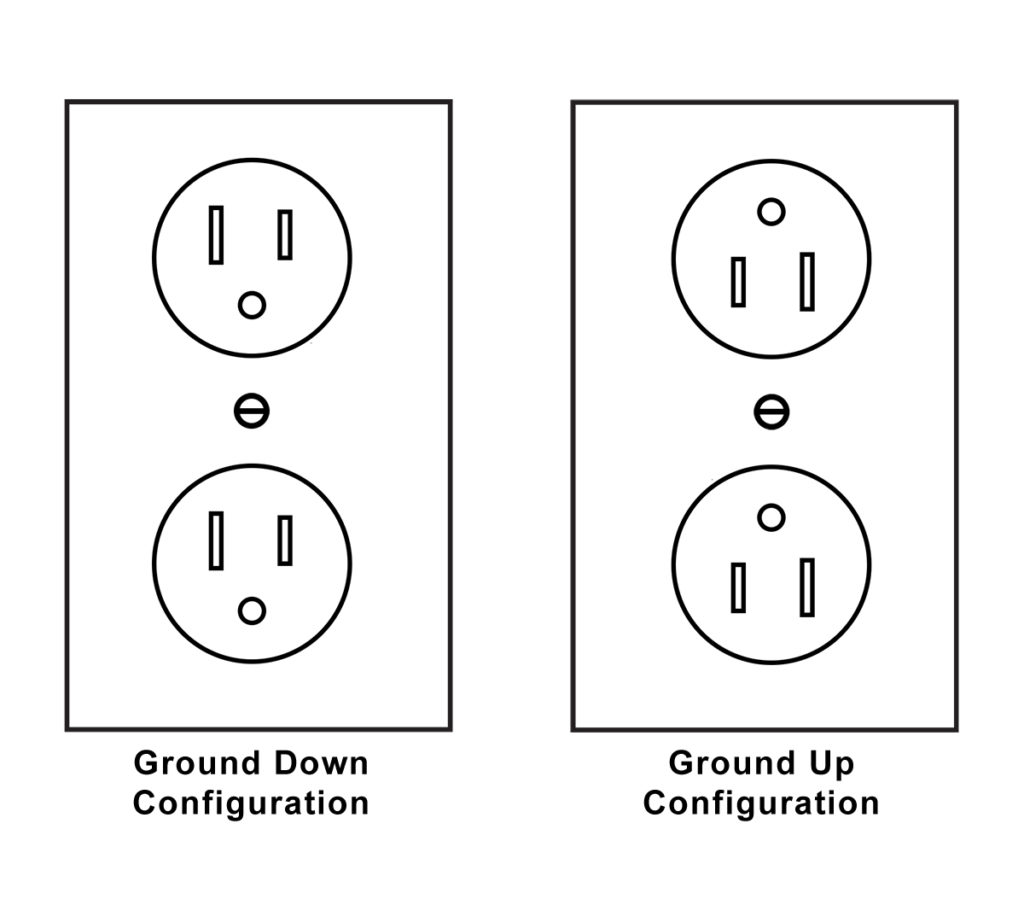

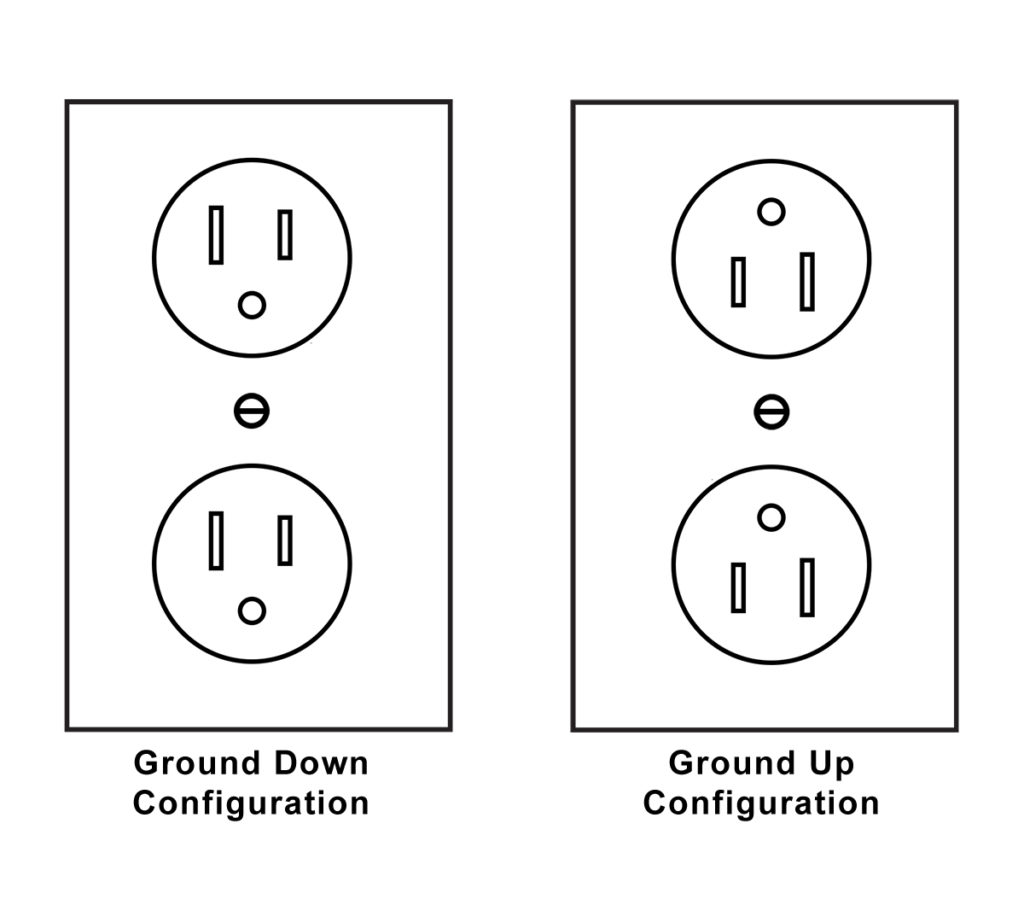

Preference question: 2 slots up or ground hole up?

Both are correct; but my dad told me the ground up is safer in case anything were to fall across with a plug partially unplugged it wouldn't do anything but if it somehow touched both hot and neutral slots it would arc and maybe cause a fire.

I always do mine 2 slots up because that's just what I've always done (little "O" faces)

Both are correct; but my dad told me the ground up is safer in case anything were to fall across with a plug partially unplugged it wouldn't do anything but if it somehow touched both hot and neutral slots it would arc and maybe cause a fire.

I always do mine 2 slots up because that's just what I've always done (little "O" faces)

The name should be upright. Ground up usually, unless it is in a Hospital.

Always listen to your Dad! ( I think there's a thread on that right now)

Levitron

Always listen to your Dad! ( I think there's a thread on that right now)

Levitron

tu- DDU * where NFL Dreams go to Die U

Yep, that's the way I always do mine, ground up!

SpreadsheetAg said:

Preference question: 2 slots up or ground hole up?

Both are correct; but my dad told me the ground up is safer in case anything were to fall across with a plug partially unplugged it wouldn't do anything but if it somehow touched both hot and neutral slots it would arc and maybe cause a fire.

I always do mine 2 slots up because that's just what I've always done (little "O" faces)

I am also a 'ground down' installer. I have heard competing theories about why one is better than the other. The leading one is, as stated, to prevent arcing should something fall into an improperly seated plug. However, 99% of everything I have ever plugged in has been designed for a 'ground down' configuration. Very few wires are designed for the other orientation and plugging something in like that can create strain on some types of wires. I install my welder plugs 'upside down' for that reason...that's the orientation that accommodates the cord.

I also figure that if my room or work area is so messy and sloppy that something metallic can fall onto a plug that somehow has miraculously become unseated and it burns everything to the ground....then maybe my time would be better spent with organization and cleaning than with contemplating outlet orientation.

Why would you put them in with the faces upside down?

When mine burnout I leave the scorch marks on the wall cause it looks like hair and than cut out the slots into crosses so everyone knows it's a dead outlet.

tu- DDU * where NFL Dreams go to Die U

62strat said:Sea Speed said:

Make a taller U, so when you place it around the screw, you then use tweezer part of strippers to make a shape similar to that of the breast cancer awareness ribbon. Then tighten the screw and snip off of you have too much excess.

Yeah don't do that. You don't want overlap on the screw.

Ground down works well in laundry rooms especially

There are safety reasons that have nothing to do with "theories" but engineering design standards that are governed by NEMA.

Imagine a desk against a wall and a paper clip or coin is pushed off the back of the desk and lays flat against the wall sliding down and bridging the prongs. Fire.

Also installed correctly the weight of the cord pulls against the ground prong but pushes the power prongs in. Thereby not allowing them to be partially removed causing a poor contact and overheating and a fire.

Imagine a desk against a wall and a paper clip or coin is pushed off the back of the desk and lays flat against the wall sliding down and bridging the prongs. Fire.

Also installed correctly the weight of the cord pulls against the ground prong but pushes the power prongs in. Thereby not allowing them to be partially removed causing a poor contact and overheating and a fire.

tu- DDU * where NFL Dreams go to Die U

I have never seen a house or building with ground up, so it seems like if it was consensus or safer or whatnot, it would have been worked in to code at some point.

Or rather, if it is, why has it not made its way in ti code.

Well all manufacturers comply with NEMA - National Electrical Manufacturers Association engineering standards.

Complying to the chart I posted

I prefer to follow engineering standards over something that is not specified in code.

Can you get an Electrical code degree?

Complying to the chart I posted

I prefer to follow engineering standards over something that is not specified in code.

Can you get an Electrical code degree?

tu- DDU * where NFL Dreams go to Die U

I'm not arguing with you man, it was just a question about why it has not made it in to code when all kinds of other nitpicky stuff has.

They've try to codify it but there are too many exceptions like in Hospitals, but only in patient areas, or that just make sense.

In industrial areas they use metal face plates. If the screw comes loose the faceplate bridges the prongs.

I used to have a copy of the Dupont engineering standard that specified the orientation of ground up

In industrial areas they use metal face plates. If the screw comes loose the faceplate bridges the prongs.

I used to have a copy of the Dupont engineering standard that specified the orientation of ground up

tu- DDU * where NFL Dreams go to Die U

Gotcha and Oh I know what you mean.

I've worked as an industrial electrician and 3/4 of the code doesn't apply to what I did. I comply with the corporate engineering standards or the EE (when they're right).

I've worked as an industrial electrician and 3/4 of the code doesn't apply to what I did. I comply with the corporate engineering standards or the EE (when they're right).

tu- DDU * where NFL Dreams go to Die U

The NEMA-5-15 is a good example. That's how I install my welder plugs...and also the way the power cord hangs properly. I think that if the standard plugs in a home are to be installed ground up, then there will need to be a consensus on cord formats.

Featured Stories

See All

Baseball Thoughts: No. 1 Aggies back top spot with T-Town takedown

by Ryan Brauninger

33:53

18h ago

5.6k