I want to try making some LED cornhole boards, specifically with an illuminated ATM logo and lit edges. Also possibly lines from the front corners to the hole. I'm planning on encasing LED strips in white epoxy and painting the boards maroon.

Does anyone know how much pigment to add to get a while epoxy that is translucent and not opaque?

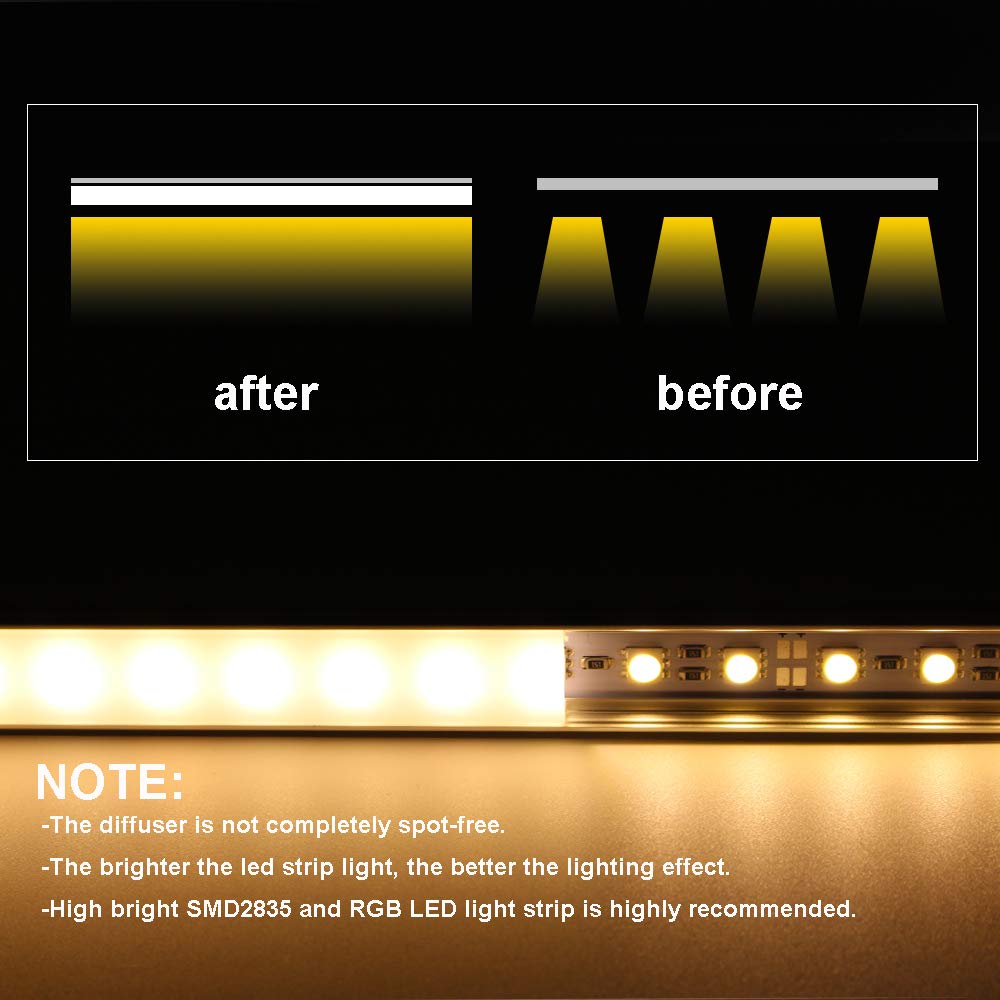

Any ideas on best depth for LED diffusion? I want to avoid seeing the individual LED's necessary the epoxy. For the logo, I'm considering epoxying without embedding LED's and then adding a light box underneath it for even diffusion, but I can't do that around the edges.

Anyone with experience with something similar?

Does anyone know how much pigment to add to get a while epoxy that is translucent and not opaque?

Any ideas on best depth for LED diffusion? I want to avoid seeing the individual LED's necessary the epoxy. For the logo, I'm considering epoxying without embedding LED's and then adding a light box underneath it for even diffusion, but I can't do that around the edges.

Anyone with experience with something similar?